Page 23 - MetalForming July 2015

P. 23

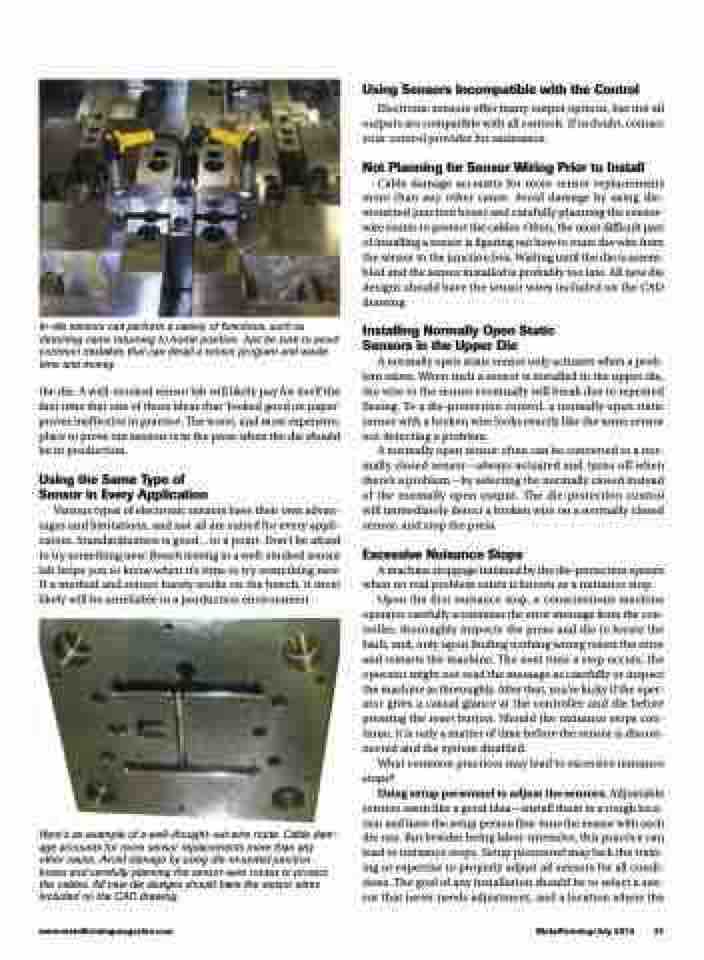

In-die sensors can perform a variety of functions, such as detecting cams returning to home position. Just be sure to avoid common mistakes that can derail a sensor program and waste time and money.

the die. A well-stocked sensor lab will likely pay for itself the first time that one of those ideas that ‘looked good on paper’ proves ineffective in practice. The worst, and most expensive, place to prove out sensors is in the press when the die should be in production.

Using the Same Type of Sensor in Every Application

Various types of electronic sensors have their own advan- tages and limitations, and not all are suited for every appli- cation. Standardization is good...to a point. Don’t be afraid to try something new. Bench testing in a well-stocked sensor lab helps you to know when it’s time to try something new. If a method and sensor barely works on the bench, it most likely will be unreliable in a production environment.

Here’s an example of a well-thought-out wire route. Cable dam- age accounts for more sensor replacements more than any other cause. Avoid damage by using die-mounted junction boxes and carefully planning the sensor-wire routes to protect the cables. All new die designs should have the sensor wires included on the CAD drawing.

Using Sensors Incompatible with the Control

Electronic sensors offer many output options, but not all outputs are compatible with all controls. If in doubt, contact your control provider for assistance.

Not Planning for Sensor Wiring Prior to Install

Cable damage accounts for more sensor replacements more than any other cause. Avoid damage by using die- mounted junction boxes and carefully planning the sensor- wire routes to protect the cables. Often, the most difficult part of installing a sensor is figuring out how to route the wire from the sensor to the junction box. Waiting until the die is assem- bled and the sensor installed is probably too late. All new die designs should have the sensor wires included on the CAD drawing.

Installing Normally Open Static Sensors in the Upper Die

A normally open static sensor only actuates when a prob- lem exists. When such a sensor is installed in the upper die, the wire to the sensor eventually will break due to repeated flexing. To a die-protection control, a normally open static sensor with a broken wire looks exactly like the same sensor not detecting a problem.

A normally open sensor often can be converted to a nor- mally closed sensor—always actuated and turns off when there’s a problem − by selecting the normally closed instead of the normally open output. The die-protection control will immediately detect a broken wire on a normally closed sensor, and stop the press.

Excessive Nuisance Stops

A machine stoppage initiated by the die-protection system when no real problem exists is known as a nuisance stop.

Upon the first nuisance stop, a conscientious machine operator carefully scrutinizes the error message from the con- troller, thoroughly inspects the press and die to locate the fault, and, only upon finding nothing wrong resets the error and restarts the machine. The next time a stop occurs, the operator might not read the message as carefully or inspect the machine as thoroughly. After that, you’re lucky if the oper- ator gives a casual glance at the controller and die before pressing the reset button. Should the nuisance stops con- tinue, it is only a matter of time before the sensor is discon- nected and the system disabled.

What common practices may lead to excessive nuisance stops?

Using setup personnel to adjust the sensors. Adjustable sensors seem like a good idea—install them in a rough loca- tion and have the setup person fine-tune the sensor with each die run. But besides being labor-intensive, this practice can lead to nuisance stops. Setup personnel may lack the train- ing or expertise to properly adjust all sensors for all condi- tions. The goal of any installation should be to select a sen- sor that never needs adjustment, and a location where the

www.metalformingmagazine.com

MetalForming/July 2015 21