Page 35 - MetalForming May 2015

P. 35

strength, power and overall configuration of every major piece of the press line, including coil-handling equipment, coil-feed systems, straightening machines and presses.

Because higher-strength materials require more stress to deform, additional servo-motor power and torque capa- bility may be needed to pull the coil material through the straightener. Increasing the back tension between the coil- feed and straightening equipment also may be required due to the higher yield strength of the material in the loop. The loop material may try to push back against the straightener or the feed system. Insufficient back tension could cause material slippage through the straightener.

Further, as coil diameter decreases, the straightener loses the mechanical advantage it had at a larger outside diame- ter. Thus; the back tension force must decrease. Fortunate- ly, manufacturers of this equipment provide electronic con- trol options for coil-handling equipment that automatically make these compensations.

Servo-Drive Technology

Stamping higher-strength steels requires higher blankhold- ing forces and punch forces that result in substantial increases in frictional forces and interface temperatures. When interface temperatures reach a critical point, lubrications may break- down and other forming and die related problems such as thermal-notching and galling can arise. When these problems

occur during a produc- tion run, it would not be uncommon to reduce press speed (strokes min.) to reduce process oper- ating temperatures and avoid thermal related forming problems.

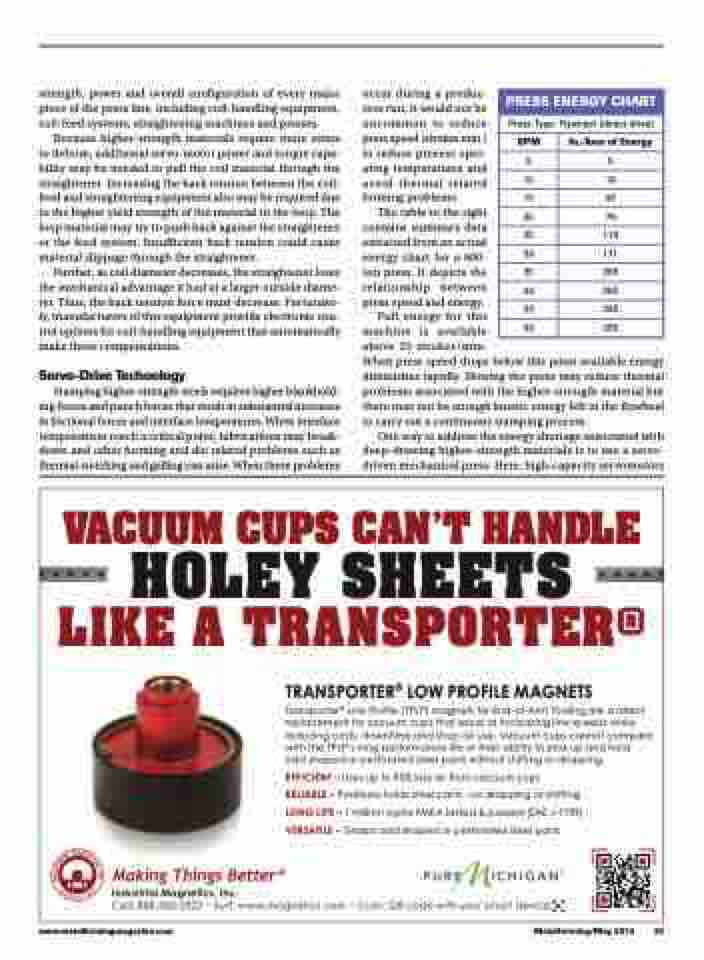

The table to the right contains summary data extracted from an actual energy chart for a 600- ton press. It depicts the relationship between press speed and energy.

Full energy for this

machine is available

above 35 strokes/min.

When press speed drops below this point available energy diminishes rapidly. Slowing the press may reduce thermal problems associated with the higher-strength material but there may not be enough kinetic energy left in the flywheel to carry out a continuous stamping process.

One way to address the energy shortage associated with deep-drawing higher-strength materials is to use a servo- driven mechanical press. Here, high-capacity servomotors

PRESS ENERGY CHART

Press Type: Flywheel (direct drive)

SPM

In.-Tons of Energy

5

5

10

19

15

43

20

76

25

119

30

171

35

285

40

285

50

285

50

285

VACUUM CUPS CAN’T HANDLE

HOLEY SHEETS

LIKE A TRANSPORTER®

TRANSPORTER® LOW PROFILE MAGNETS

Transporter® ��� ������ ������ ������� ��� ���������� ������� ��� � ������ ����������� ��� ������ ���� ���� ����� �� ���������� ���� ������ ����� �������� ������ �������� ��� ���� ��� ���� ������ ���� ������ ������� ���� ��� ������ ���� ����������� ���� �� ����� ������� �� ���� �� ��� ���� ��� ������ �� ���������� ����� ����� ������� �������� �� ���������

EFFICIENT – ���� �� �� ��� ���� ��� ���� ������ ���� RELIABLE – ���������� ����� ����� ����� � �� �������� �� �������� LONG LIFE – � ������� ����� ���� ������ � ������ ���� ������� VERSATILE – ������ ��� ������ �� ���������� ����� �����

www.metalformingmagazine.com

MetalForming/May 2015 33