Page 30 - MetalForming March 2015

P. 30

X

Y

R

These tips and tricks ensure that fabricators get the most out of their tooling.

Fabricators looking to improve their CNC punching need only look beyond what they’re doing now. Chances are, tools and techniques already available are worth checking out. Start with these tools, their uses and surprising capabilities.

Four-Way Radius Tool— Often Overlooked for Quick Edge Rounding

Frequently, fabricators use special tools in a CNC punch press’ auto-index station to round corners on parts. Rounded edges often are preferred because they provide a finished appearance and eliminate injury-caus- ing sharp, pointed corners.

A four-way radius tool allows fabri- cators to achieve rounded corners with just one hit instead of rougher nib-

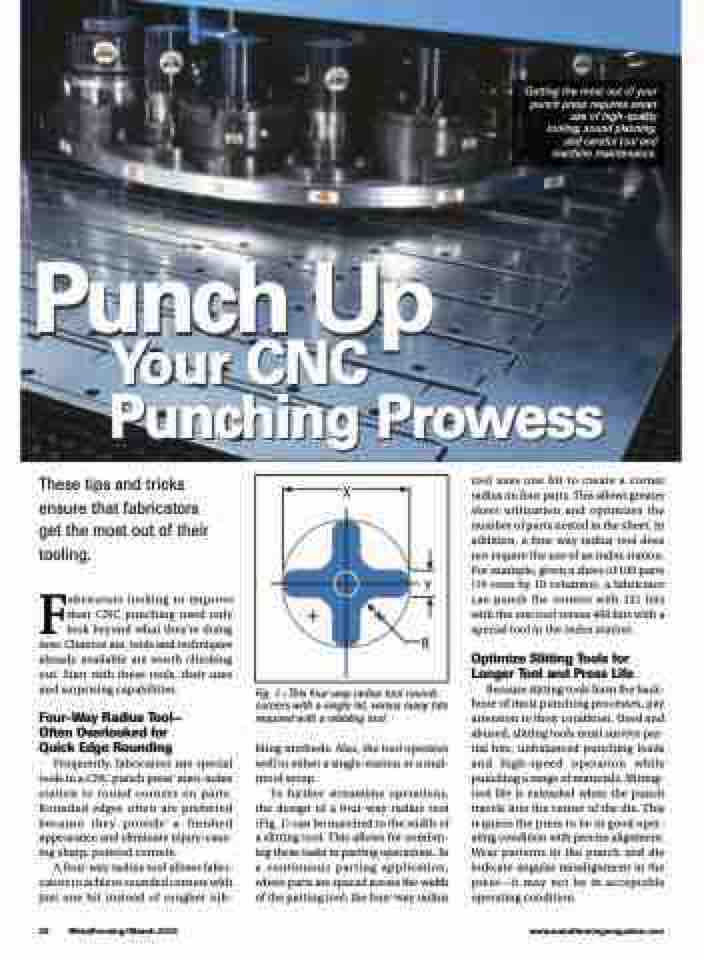

Fig. 1—This four-way radius tool rounds corners with a single hit, versus many hits required with a nibbling tool.

bling methods. Also, the tool operates well in either a single-station or a mul- titool setup.

To further streamline operations, the design of a four-way radius tool (Fig. 1) can be matched to the width of a slitting tool. This allows for combin- ing these tasks in parting operations. In a continuous parting application, where parts are spaced across the width of the parting tool, the four-way radius

tool uses one hit to create a corner radius on four parts. This allows greater sheet utilization and optimizes the number of parts nested in the sheet. In addition, a four-way radius tool does not require the use of an index station. For example, given a sheet of 100 parts (10 rows by 10 columns), a fabricator can punch the corners with 121 hits with the one tool versus 400 hits with a special tool in the index station.

Optimize Slitting Tools for Longer Tool and Press Life

Because slitting tools form the back- bone of most punching processes, pay attention to their condition. Used and abused, slitting tools must survive par- tial hits, unbalanced punching loads and high-speed operation while punching a range of materials. Slitting- tool life is extended when the punch travels into the center of the die. This requires the press to be in good oper- ating condition with precise alignment. Wear patterns in the punch and die indicate angular misalignment in the press—it may not be in acceptable operating condition.

28 MetalForming/March 2015

www.metalformingmagazine.com

Punch Up

Punch Up

Your CNC

Your CNC

Punching Prowess

Punching Prowess

Getting the most out of your punch press requires smart use of high-quality tooling, sound planning, and careful tool and machine maintenance.