Page 28 - MetalForming December 2014

P. 28

Waterjet-Cutting Machines

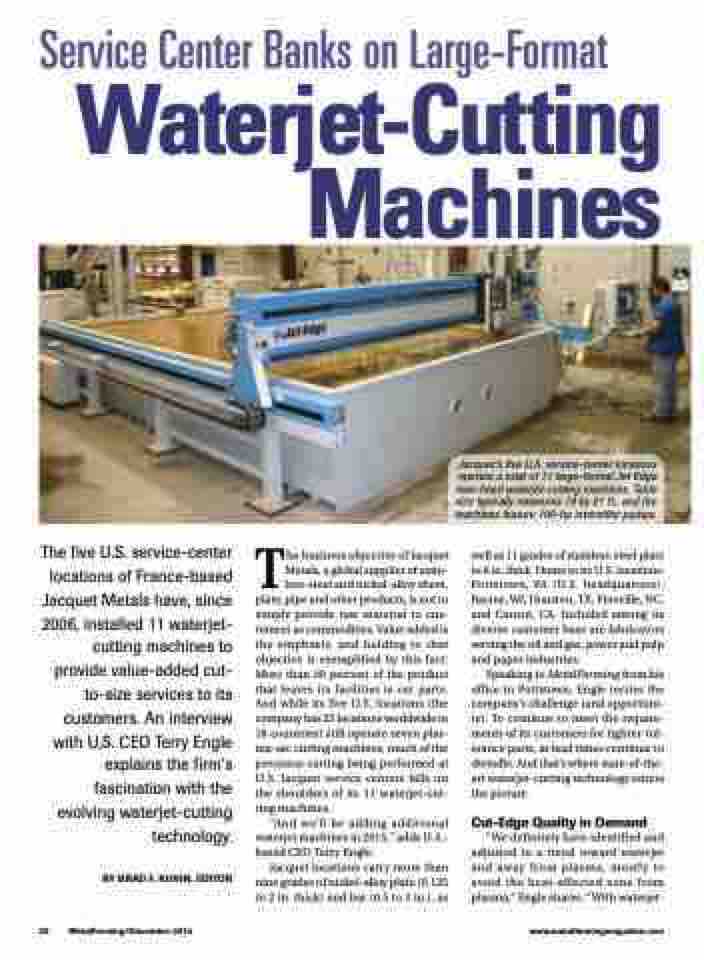

Jacquet’s five U.S. service-center locations operate a total of 11 large-format Jet Edge twin-head waterjet-cutting machines. Table size typically measures 13 by 21 ft., and the machines feature 100-hp intensifier pumps.

The five U.S. service-center locations of France-based Jacquet Metals have, since 2006, installed 11 waterjet- cutting machines to provide value-added cut- to-size services to its customers. An interview with U.S. CEO Terry Engle explains the firm’s fascination with the evolving waterjet-cutting technology.

BY BRAD F. KUVIN, EDITOR

The business objective of Jacquet Metals, a global supplier of stain- less-steel and nickel-alloy sheet, plate, pipe and other products, is not to simply provide raw material to cus- tomers as commodities. Value added is the emphasis, and holding to that objective is exemplified by this fact: More than 90 percent of the product that leaves its facilities is cut parts. And while its five U.S. locations (the company has 23 locations worldwide in 18 countries) still operate seven plas- ma-arc cutting machines, much of the precision cutting being performed at U.S. Jacquet service centers falls on the shoulders of its 11 waterjet-cut- ting machines.

“And we’ll be adding additional waterjet machines in 2015,” adds U.S.- based CEO Terry Engle.

Jacquet locations carry more than nine grades of nickel-alloy plate (0.125 to 2 in. thick) and bar (0.5 to 3 in.), as

well as 11 grades of stainless-steel plate to 6 in. thick. Home to its U.S. locations: Pottstown, PA (U.S. headquarters), Racine, WI, Houston, TX, Pineville, NC, and Carson, CA. Included among its diverse customer base are fabricators serving the oil and gas, power and pulp and paper industries.

Speaking to MetalForming from his office in Pottstown, Engle recites the company’s challenge (and opportuni- ty): To continue to meet the require- ments of its customers for tighter-tol- erance parts, as lead times continue to dwindle. And that’s where state-of-the- art waterjet-cutting technology enters the picture.

Cut-Edge Quality in Demand

“We definitely have identified and adjusted to a trend toward waterjet and away from plasma, mostly to avoid the heat-affected zone from plasma,” Engle shares. “With waterjet-

26

MetalForming/December 2014

www.metalformingmagazine.com