Page 56 - MetalForming October 2014

P. 56

Previews

Software Release Offers Solutions for Trim-Line Development,

Hot Forming and More

Engineering Technology Associates

The trim-line development add-on offers multiple-stage sim- ulation capabilities, using an iterative approach for simulating trim- ming during metal stamping to ensure that final trim-line result matches the target line.

Booth B1506

The rotary tube-bending add-on allows users to calculate the tube (product) centerline, generate the bending process auto- matically, edit, review and analyze the bending process through simulation. Users also can preview tool movement through the bend- ing process via the simulation. www.eta.com

Engineering Technology Associates, Inc. (ETA) announces the release of Dynaform Version 5.9.2, simulation software that

analyzes the entire die system and allows organizations to bypass soft tooling, reducing tryout time, lowering costs and improv- ing cycle times and productivity. The latest release offers many new and improved features, as well as brand new add-ons for trim- line development, rotary tube-bending design and analysis, hot forming and die structure cooling.

On display will be Delta’s high-performance motion-control product line that includes the RMC75 two-axis and RMC150 eight-axis controllers, which provide precise closed-loop position, velocity, pressure, force, and position-pressure or position-force control for electric, hydraulic and pneumatic applications. Designing with the controllers is supported by extensive information on the company’s website and a pow- erful suite of development software called RMCtools, which includes automated wizards for application tuning, motion pro- gramming and plotting of motion results.

www.deltamotion.com

Motion Controllers for Electric,

Hydraulic and Pneumatic Applications

Delta Computer Systems Booth B1337

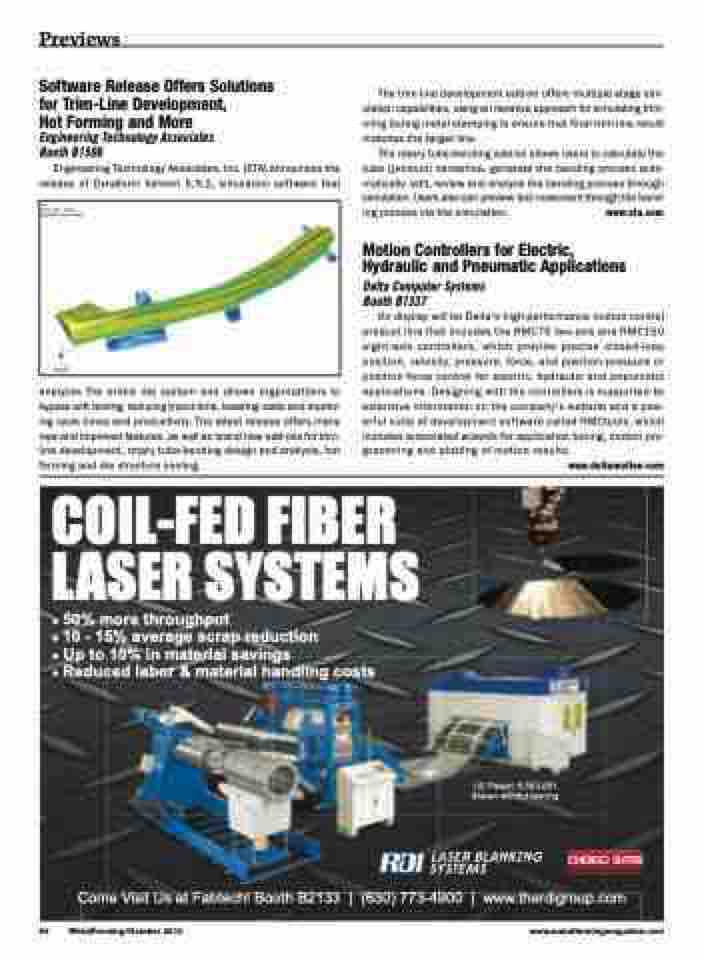

COIL-FED FIBER LASER SYSTEMS

� ��� ���� ����������

� �� � ��� ������� ����� ���������

� �� �� ��� �� �������� �������

� ������� ����� � �������� �������� �����

US Patent: 6,563,081 Shown without fencing

Come Visit Us at Fabtech! Booth B2133 | (630) 773-4900 | www.therdigroup.com

54

MetalForming/October 2014 www.metalformingmagazine.com