Page 22 - MetalForming August 2014

P. 22

������� �������� ��� ����� � ������

����� ����� ������ ��� ��������

�������� �� ������ ��� ����� ��������

���� ����� ����� ��������

����� ����� ���������� �������� ���� ���������� �������

������������� ����� ��������

������ ���� ���������� �������� ����������

����� ����� ������ � ��������

������ ����� �������� ������ ��� �������

��������� ���� �������

���� � ���� ��������� ��������

����� ������� � ���� ����������

���� �� ��� ���

������������ ������������������������������ ����������������������������

20 MetalForming/August 2014

www.metalformingmagazine.com

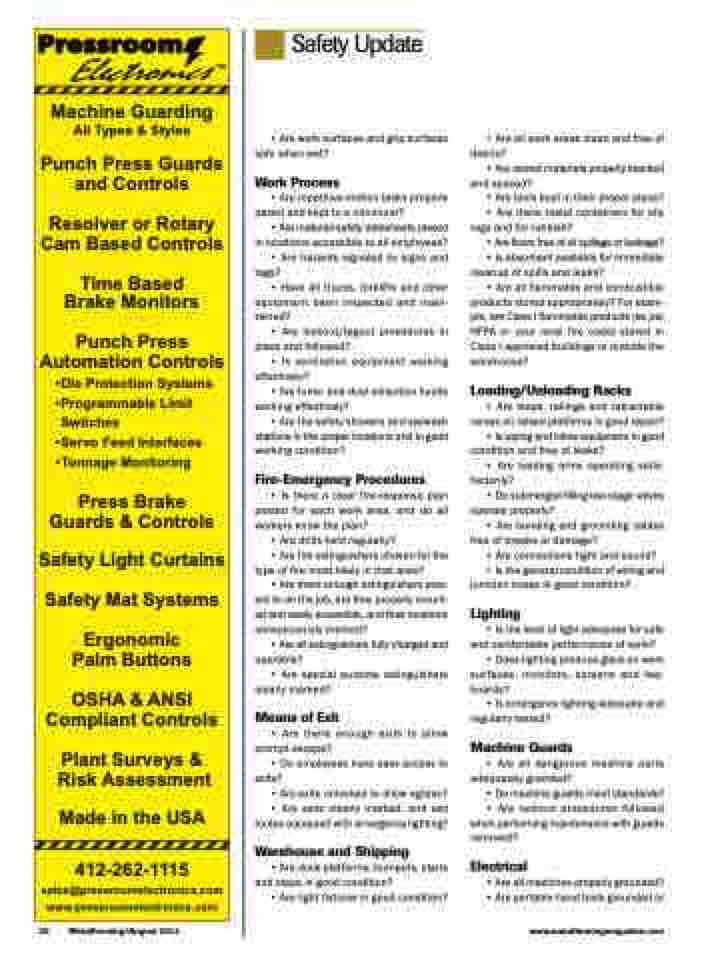

Safety Update

• Are work surfaces and grip surfaces safe when wet?

• Are all work areas clean and free of debris?

Work Process

• Are stored materials properly stacked and spaced?

• Are repetitive-motion tasks properly paced and kept to a minimum?

• Are tools kept in their proper place?

• Are material-safety datasheets placed in locations accessible to all employees? • Are hazards signaled by signs and

• Are there metal containers for oily rags and for rubbish?

tags?

• Have all trucks, forklifts and other

• Is absorbent available for immediate cleanup of spills and leaks?

equipment been inspected and main- tained?

• Are all flammable and combustible products stored appropriately? For exam- ple, are Class I flammable products (as per NFPA or your local fire code) stored in Class I approved buildings or outside the warehouse?

• Are lockout/tagout procedures in place and followed?

• Is ventilation equipment working effectively?

• Are fume- and dust-collection hoods working effectively?

Loading/Unloading Racks

• Are the safety showers and eyewash stations in the proper locations and in good working condition?

• Are steps, railings and retractable ramps on raised platforms in good repair? • Is piping and inline equipment in good

Fire-Emergency Procedures

factorily?

• Do submerged filling two-stage valves

• Is there a clear fire-response plan posted for each work area, and do all workers know the plan?

operate properly?

• Are bonding and grounding cables

• Are drills held regularly?

free of breaks or damage?

• Are connections tight and sound? • Is the general condition of wiring and

• Are fire extinguishers chosen for the type of fire most likely in that area?

junction boxes in good condition?

• Are there enough extinguishers pres- ent to do the job, are they properly mount- ed and easily accessible, and their locations conspicuously marked?

Lighting

• Are all extinguishers fully charged and operable?

• Is the level of light adequate for safe and comfortable performance of work?

• Are special purpose extinguishers clearly marked?

• Does lighting produce glare on work surfaces, monitors, screens and key- boards?

Means of Exit

• Is emergency lighting adequate and regularly tested?

• Are there enough exits to allow prompt escape?

Machine Guards

• Do employees have easy access to exits?

• Are all dangerous machine parts adequately guarded?

• Are exits unlocked to allow egress?

• Do machine guards meet standards?

• Are exits clearly marked, and exit routes equipped with emergency lighting?

• Are lockout procedures followed when performing maintenance with guards removed?

Warehouse and Shipping

• Are dock platforms, bumpers, stairs and steps in good condition?

Electrical

• Are light fixtures in good condition?

• Are all machines properly grounded? • Are portable hand tools grounded or

• Are floors free of oil spillage or leakage?

condition and free of leaks?

• Are loading arms operating satis-