Page 5 - MetalForming June 2014

P. 5

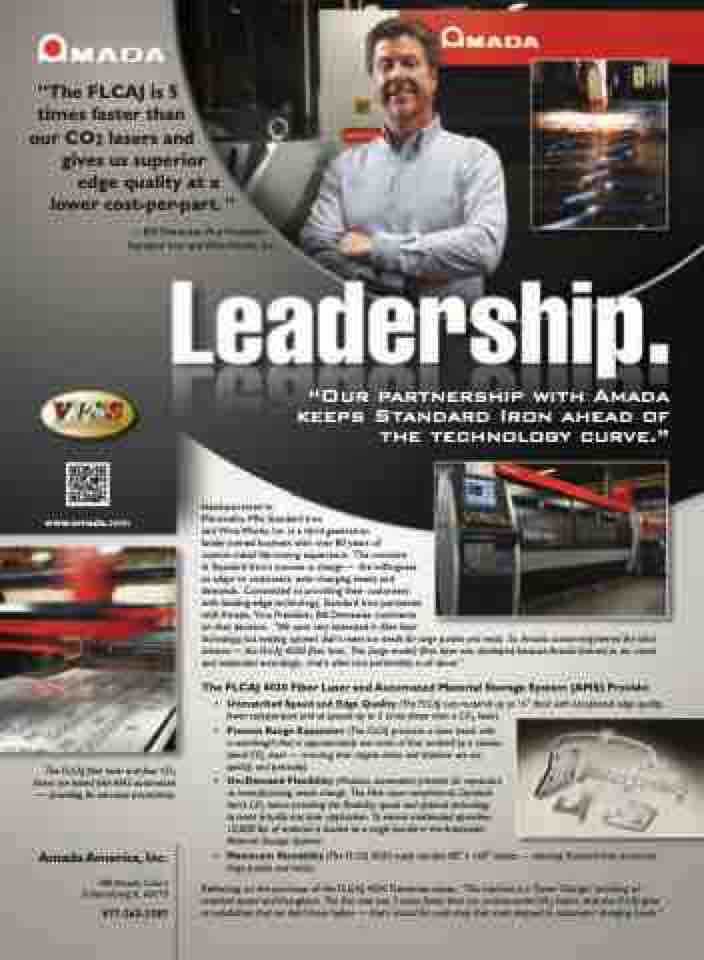

“The FLCAJ is 5

times faster than our CO2 lasers and

gives us superior edge quality at a

lower cost-per-part. ”

— Bill Demeules,Vice President Standard Iron and Wire Works, Inc.

www.amada.com

“Our partnership with Amada keeps Standard Iron ahead of the technology curve.”

Headquartered in

Monticello, MN, Standard Iron

and Wire Works, Inc. is a third generation

family-owned business with over 80 years of

custom metal fabricating experience. The constant

in Standard Iron’s success is change — the willingness

to adapt to customers’ ever-changing needs and

demands. Committed to providing their customers

with leading-edge technology, Standard Iron partnered

with Amada. Vice President, Bill Demeules comments

on that decision. “We were very interested in fiber laser

technology, but existing systems didn’t meet our needs for large panels and nests. So, Amada custom-engineered the ideal solution — the FLCAJ 4020 fiber laser. This (large model) fiber laser was developed because Amada listened to our needs and responded accordingly... that’s what true partnership is all about.”

The FLCAJ 4020 Fiber Laser and Automated Material Storage System (AMS) Provide:

• Unmatched Speed and Edge Quality (The FLCAJ cuts material up to 1/4" thick with exceptional edge quality,

lower cost-per-part and at speeds up to 5 times faster than a CO2 laser).

• Process Range Expansion (The FLCAJ produces a laser beam with

a wavelength that is approximately one tenth of that emitted by a conven- tional CO2 laser — ensuring that copper, brass and titanium are cut quickly and precisely).

• On-Demand Flexibility (Modular automation provides for expansion as manufacturing needs change. The Fiber laser compliments Standard Iron’s CO2 lasers providing the flexibility, speed and optimal technology

to meet virtually any laser application. To ensure unattended operation, 10,000 lbs. of material is loaded as a single bundle in the Automated Material Storage System).

• Maximum Versatility (The FLCAJ 4020 easily handles 80" x 160" sheets — allowing Standard Iron to process large panels and nests).

Reflecting on the purchase of the FLCAJ 4020 Demeules states, “This machine is a ‘Game Changer’ providing un- matched speed and throughput. The first nest was 5 times faster than our current-model CO2 lasers. And, the FLCAJ gives us capabilities that we didn’t have before — that’s crucial for a job shop that must respond to customers’ changing needs.”

The FLCAJ fiber laser and four CO2 lasers are linked with AMS automation — providing for non-stop productivity.

Amada America, Inc.

180 Amada Court Schaumburg, IL 60173

877-262-3287