Page 40 - MetalForming June 2014

P. 40

The Science of Forming By Stuart Keeler

Strain-Rate Hardening: Small Number, Big Impact

Strain ε

+m

–m

σ=Κˊεm

Most discussions about material properties and sheetmetal formability revolve around yield strength, tensile strength and total elongation, with hardness values often thrown in for good measure. These properties historically have rep- resented the key links between the formability needs of stamped parts and the capabilities of the material being supplied.

During the 1940s the information link greatly improved when researchers took a serious look at workhardening (work strengthening) during deforma- tion. They developed an equation called the Power Law to relate how the stress to deform a material increases as the strain (deformation) increases. The equation connecting true stress and true strain:

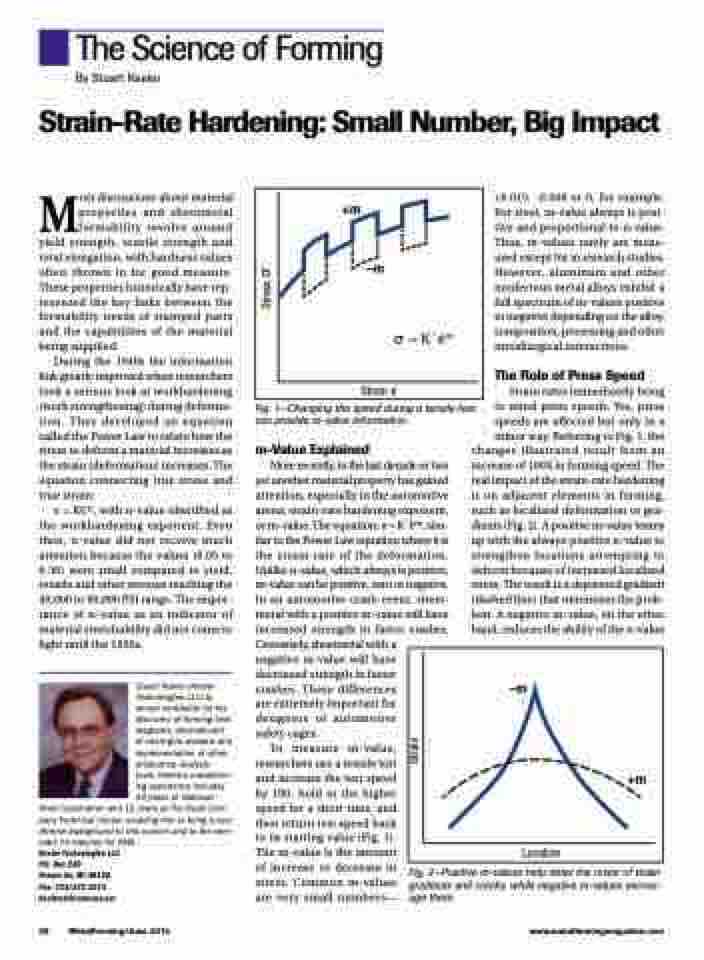

Fig. 1—Changing the speed during a tensile test can provide m-value information.

+0.015, -0.008 or 0, for example. For steel, m-value always is posi- tive and proportional to n-value. Thus, m-values rarely are meas- ured except for in research studies. However, aluminum and other nonferrous metal alloys exhibit a full spectrum of m-values positive to negative depending on the alloy, composition, processing and other metallurgical interactions.

The Role of Press Speed

Strain rates immediately bring to mind press speeds. Yes, press speeds are affected but only in a minor way. Referring to Fig. 1, the

n

σ = KЄ , with n-value identified as

m-Value Explained

More recently, in the last decade or two yet another material property has gained attention, especially in the automotive arena: strain-rate hardening exponent,

changes illustrated result from an increase of 100X in forming speed. The real impact of the strain-rate hardening is on adjacent elements in forming, such as localized deformation or gra- dients (Fig. 2). A positive m-value teams up with the always-positive n-value to strengthen locations attempting to deform because of increased localized stress. The result is a depressed gradient (dashed line) that minimizes the prob- lem. A negative m-value, on the other hand, reduces the ability of the n-value

the workhardening exponent. Even then, n-value did not receive much attention because the values (0.05 to 0.30) were small compared to yield, tensile and other stresses reaching the 40,000 to 80,000 PSI range. The impor- tance of n-value as an indicator of material stretchability did not come to light until the 1950s.

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis

tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC P.O. Box 283

Grosse Ile, MI 48138 Fax: 734/671-2271 keeltech@comcast.net

ilar to the Power Law equation where ε̇ is the strain rate of the deformation. Unlike n-value, which always is positive, m-value can be positive, zero or negative. In an automotive crash event, sheet- metal with a positive m-value will have increased strength in faster crashes. Conversely, sheetmetal with a

m

or m-value. The equation: σ = K ́ε̇ , sim-

–m

Location

+m

negative m-value will have decreased strength in faster crashes. These differences are extremely important for designers of automotive safety cages.

To measure m-value, researchers use a tensile test and increase the test speed by 100, hold at the higher speed for a short time, and then return test speed back to its starting value (Fig. 1). The m-value is the amount of increase or decrease in stress. Common m-values are very small numbers—

Fig. 2—Positive m-values help deter the onset of strain gradients and cracks, while negative m-values encour- age them.

38 MetalForming/June 2014

www.metalformingmagazine.com

Strain

Stress σ