Page 18 - MetalForming June 2014

P. 18

Lubrication Efficiency Provides Investment Cash Flow

By dramatically reducing stamping-lubricant consumption and related maintenance headaches and costs, this high-speed stamper frees up cash to support press rebuilds and repairs, as it looks to make a big splash

in the lithium-battery and medical/dental markets.

BY BRAD F. KUVIN, EDITOR

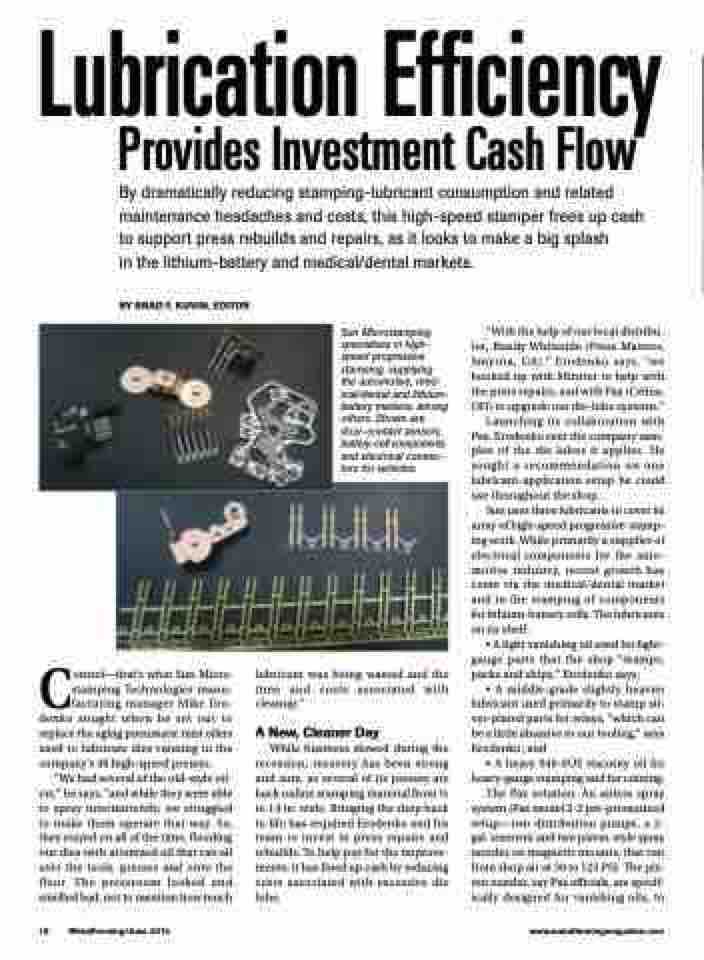

Sun Microstamping specializes in high- speed progressive stamping, supplying the automotive, med- ical/dental and lithium- battery markets, among others. Shown are door-contact sensors, battery-cell components and electrical connec- tors for vehicles.

“With the help of our local distribu- tor, Randy Whiteside (Press Masters, Smyrna, GA),” Erodenko says, “we hooked up with Minster to help with the press repairs, and with Pax (Celina, OH) to upgrade our die-lube systems.”

Launching its collaboration with Pax, Erodenko sent the company sam- ples of the die lubes it applies. He sought a recommendation on one lubricant-application setup he could use throughout the shop.

Sun uses three lubricants to cover its array of high-speed progressive-stamp- ing work. While primarily a supplier of electrical components for the auto- motive industry, recent growth has come via the medical/dental market and in the stamping of components for lithium-battery cells. The lubricants on its shelf:

• A light vanishing oil used for light- gauge parts that the shop “stamps, packs and ships,” Erodenko says;

• A middle-grade slightly heavier lubricant used primarily to stamp sil- ver-plated parts for relays, “which can be a little abrasive to our tooling,” says Erodenko; and

• A heavy 940-SUS viscosity oil for heavy-gauge stamping and for coining. The Pax solution: An airless spray system (Pax model 2-2 pre-pressurized setup—two distribution pumps, a 2- gal. reservoir and two piston-style spray nozzles on magnetic mounts, that run from shop air at 30 to 125 PSI. The pis- ton nozzles, say Pax officials, are specif- ically designed for vanishing oils, to

Control—that’s what Sun Micro- stamping Technologies manu- facturing manager Mike Ero- denko sought when he set out to replace the aging pneumatic mist oilers used to lubricate dies running in the company’s 48 high-speed presses.

“We had several of the old-style oil- ers,” he says, “and while they were able to spray intermittently, we struggled to make them operate that way. So, they stayed on all of the time, flooding our dies with atomized oil that ran all over the tools, presses and onto the floor. The pressroom looked and smelled bad, not to mention how much

lubricant was being wasted and the time and costs associated with cleanup.”

A New, Cleaner Day

While business slowed during the recession, recovery has been strong and sure, as several of its presses are back online stamping material from 1⁄2 to 14 in. wide. Bringing the shop back to life has required Erodenko and his team to invest in press repairs and rebuilds. To help pay for the improve- ments, it has freed up cash by reducing costs associated with excessive die lube.

16 MetalForming/June 2014

www.metalformingmagazine.com