Page 5 - MetalForming May 2014

P. 5

“Automatic tool changes

give BR Metal 5 more bending

hours per day and guaranteed

repeatability.”

— Boyd Dittmer, President

BR Metal Technology, Inc.

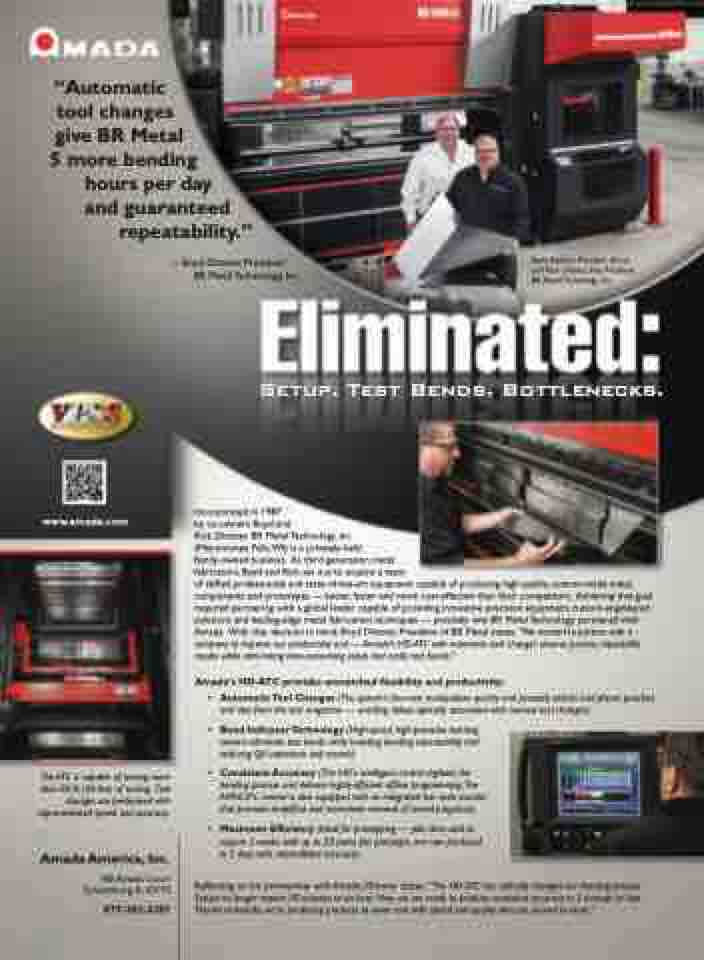

Boyd Dittmer, President (front) and Rick Dittmer,Vice President BR Metal Technology, Inc.

www.amada.com

Setup. Test Bends. Bottlenecks.

Incorporated in 1987

by co-owners Boyd and

Rick Dittmer, BR Metal Technology, Inc.

(Menomonee Falls,WI) is a privately-held,

family-owned business. As third generation metal

fabricators, Boyd and Rick set out to acquire a team

of skilled professionals and state-of-the-art equipment capable of producing high quality, custom-made metal components and prototypes — better, faster and more cost-effective than their competitors. Achieving that goal required partnering with a global leader capable of providing innovative precision equipment, custom-engineered solutions and leading-edge metal fabrication techniques — precisely why BR Metal Technology partnered with Amada. With that decision in mind, Boyd Dittmer, President of BR Metal states, “We wanted to partner with a company to improve our productivity and — Amada’s HD-ATC with automatic tool changer ensures precise, repeatable results while eliminating time-consuming setup and costly test bends.”

Amada’s HD-ATC provides unmatched flexibility and productivity:

• Automatic Tool Changes (The system’s four-axis manipulator quickly and precisely selects and places punches

and dies from the tool magazine — avoiding delays typically associated with manual tool changes).

• Bend Indicator Technology (High-speed, high-precision bending sensors eliminate test bends while boosting bending repeatability and reducing QA inspection and rework).

• Consistent Accuracy (The HD’s intelligent control digitizes the bending process and delivers highly-efficient offline programming.The AMNC/PC control is also equipped with an integrated bar code scanner that provides simplified and immediate retrieval of stored programs).

• Maximum Efficiency (Ideal for prototyping — jobs that used to require 2 weeks with up to 20 parts per prototype, are now produced in 2 days with unparalleled accuracy).

Reflecting on his partnership with Amada, Dittmer states, “The HD-ATC has radically changed our bending process. Setups no longer require 30 minutes to an hour. Now, we are ready to produce consistent accuracy in 2 minutes or less. Thanks to Amada, we’re producing products at lower cost with speed and quality that are second to none.”

The ATC is capable of storing more than 86 ft. (26.4m) of tooling. Tool changes are performed with unprecedented speed and accuracy.

Amada America, Inc.

180 Amada Court Schaumburg, IL 60173

877-262-3287