Page 20 - MetalForming May 2014

P. 20

Advanced High Strength Steels

from production of the steel all the way to vehicle recycling.

Metallurgy: Conventional low- and high-strength steels have a single- phase ferrite microstructure. In com- parison, AHSS microstructures contain one or more phases other than ferrite, including martensite, bainite, austen- ite, retained austenite and other con- figurations of grain modification. Explanations of each type of AHSS pro- vide an understanding of the mechan- ical properties and forming behavior

of the different steels. Highlighted is the tremendous progress made to improve ductility while preserving strength levels.

Mechanical Properties: Many OEMs hand production and even die design and build off to their Tier 1 and lower suppliers. Thus, suppliers must under- stand not only the three commonly used properties of yield strength, ten- sile strength and total elongation, but also less familiar terms such as workhardening (n-value), diffuse

(width) necking, local (through-thick- ness) necking and strain-rate harden- ing. Global ordering and shipping of steels becomes more demanding as different parts of the world use different procedures to measure the same prop- erties. Test procedures for total elon- gation, for example, may require 2- or 3-in. gauge lengths plus different widths. So, a single steel sample could have a total elongation of 34 percent or 39 percent depending on the active test procedure.

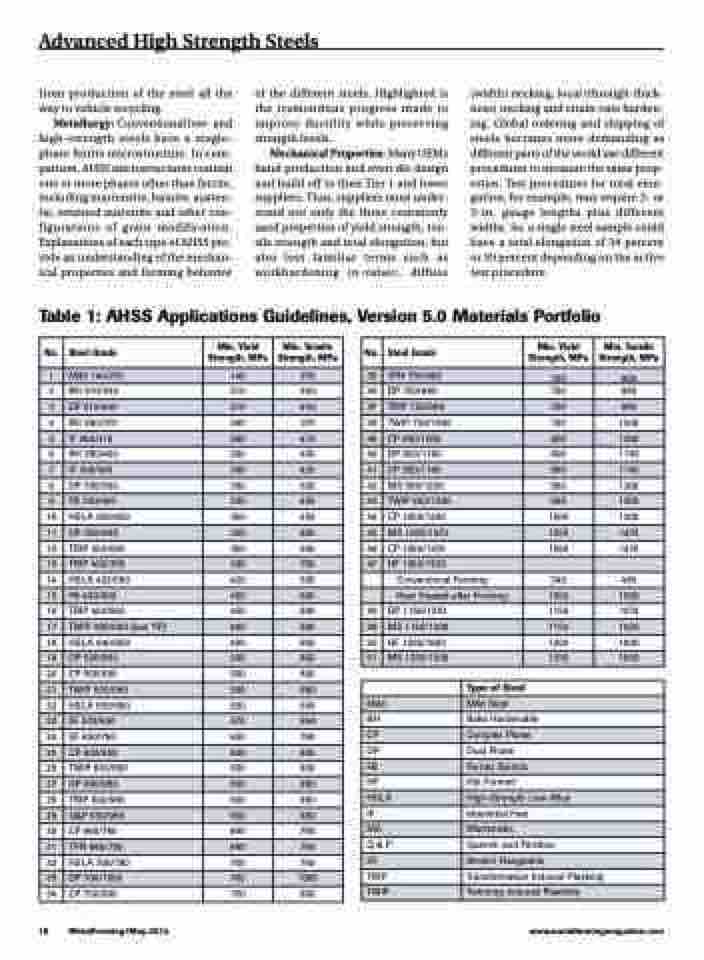

Table 1: AHSS Applications Guidelines, Version 5.0 Materials Portfolio

No.

Steel Grade

Min. Yield Strength, MPa

Min. Tensile Strength, MPa

1

Mild 140/270

140

270

2

BH 210/340

210

340

3

DP 210/440

210

440

4

BH 260/370

260

370

5

IF 260/410

260

410

6

BH 280/400

280

400

7

IF 300/420

300

420

8

DP 300/500

300

500

9

FB 330/450

330

450

10

HSLA 350/450

350

450

11

DP 350/600

350

600

12

TRIP 350/600

350

600

13

TRIP 400/700

400

700

14

HSLA 420/500

420

500

15

FB 450/600

450

600

16

TRIP 450/800

450

800

17

TWIP 480/900 (low YP)

480

900

18

HSLA 490/600

490

600

19

DP 500/800

500

800

20

CP 500/800

500

800

21

TWIP 500/980

500

980

22

HSLA 550/650

550

650

23

SF 570/640

570

640

24

SF 600/780

600

780

25

CP 600/900

600

900

26

TWIP 600/900

600

900

27

DP 600/980

600

980

28

TRIP 600/980

600

980

29

Q&P 650/980

650

980

30

CP 680/780

680

780

31

TPN 680/780

680

780

32

HSLA 700/780

700

780

33

DP 700/1000

700

1000

34

CP 750/900

750

900

No.

Steel Grade

Min. Yield Strength, MPa

Min. Tensile Strength, MPa

35

TPN 750/900

750

900

36

DP 750/980

750

980

37

TRIP 750/980

750

980

38

TWIP 750/1000

750

1000

39

CP 800/1000

800

1000

40

DP 800/1180

800

1180

41

CP 850/1180

850

1180

42

MS 950/1200

950

1200

43

TWIP 950/1200

950

1200

44

CP 1000/1200

1000

1200

45

MS 1050/1470

1050

1470

46

CP 1050/1470

1050

1470

47

HF 1050/1500

Conventional Forming

340

480

Heat Treated after Forming

1050

1500

48

DP 1150/1270

1150

1270

49

MS 1150/1400

1150

1400

50

HF 1200/1900

1200

1900

51

MS 1250/1500

1250

1500

Type of Steel

Mild

Mild Steel

BH

Bake Hardenable

CP

Complex Phase

DP

Dual Phase

FB

Ferritic Bainitic

HF

Hot Formed

HSLA

High-Strength Low-Alloy

IF

Interstitial Free

MS

Martensitic

Q&P

Quench and Partition

SF

Stretch Flangeable

TRIP

Transformation Induced Plasticity

TWIP

Twinning Induced Plasticity

18 MetalForming/May 2014 www.metalformingmagazine.com