Page 5 - MetalForming March 2014

P. 5

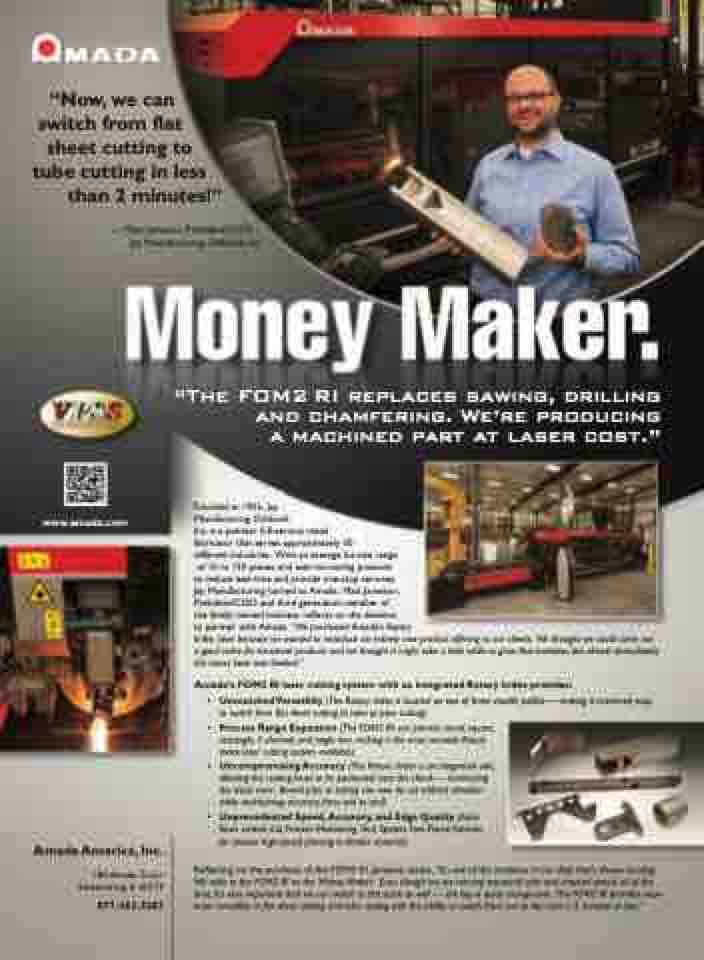

“Now, we can switch from flat

sheet cutting to tube cutting in less

than 2 minutes!”

— Matt Jameson, President/COO Jay Manufacturing Oshkosh, Inc.

www.amada.com

“The FOM2 RI replaces sawing, drilling and chamfering. We’re producing a machined part at laser cost.”

Founded in 1955, Jay

Manufacturing Oshkosh,

Inc. is a premier full-service metal

fabricator that serves approximately 50

different industries. With an average lot size range

of 10 to 150 pieces, and ever-increasing pressure

to reduce lead time and provide one-stop services,

Jay Manufacturing turned to Amada. Matt Jameson,

President/COO and third generation member of

the family-owned business reflects on the decision

to partner with Amada. “We purchased Amada’s Rotary

Index laser because we wanted to introduce an entirely new product offering to our clients. We thought we could carve out a good niche for structural products and we thought it might take a little while to grow that business, but almost immediately the rotary laser was booked.”

Amada’s FOM2 RI laser cutting system with an integrated Rotary Index provides:

• Unmatched Versatility (The Rotary Index is located on one of three shuttle pallets — making it extremely easy

to switch from flat sheet cutting to tube or pipe cutting).

• Process Range Expansion (The FOM2 RI can process round, square, rectangle, C-channel, and angle iron, making it the most versatile Rotary Index laser cutting system available).

• Uncompromising Accuracy (The Rotary Index is an integrated unit, allowing the cutting head to be positioned near the chuck— minimizing the dead zone. Bowed pipe or tubing can now be cut without vibration while maintaining accuracy from end to end).

• Unprecedented Speed, Accuracy, and Edge Quality (Auto- focus control. Cut Process Monitoring. And, Spatter Free Pierce function for cleaner high-speed piercing in thicker material).

Reflecting on the purchase of the FOM2 RI, Jameson states, “It’s one of the machines in our shop that’s always running. We refer to the FOM2 RI as the ‘Money Maker’. Even though we are running structural tube and channel almost all of the time, it’s very important that we can switch to flat stock as well — the key is quick change-over. The FOM2 RI provides maxi- mum versatility in flat sheet cutting and tube cutting with the ability to switch from one to the next in 2 minutes or less.”

Amada America, Inc.

180 Amada Court Schaumburg, IL 60173

877-262-3287