Page 26 - MetalForming March 2014

P. 26

Waterjet-Cutting Technology

CAM Software Develops 2D Profiles, 3D Pathing

Using new Intelli-Cam advanced computer-aided manufacturing soft- ware from Omax Corp., Kent, WA, engi- neers can generate 2D and 3D waterjet- cutting tool paths from 3D models. Import a 3D file in one of the many supported file types and the 3D object

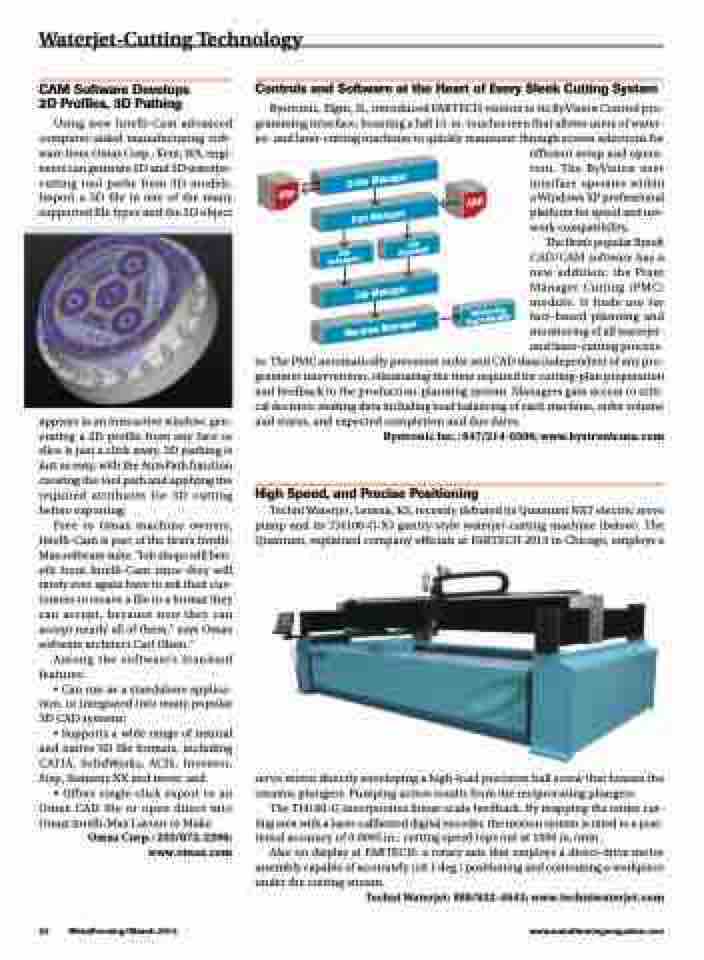

Controls and Software at the Heart of Every Sleek Cutting System

Bystronic, Elgin, IL, introduced FABTECH visitors to its ByVision Control pro- gramming interface, boasting a full 15-in. touchscreen that allows users of water- jet- and laser-cutting machines to quickly maneuver through screen selections for

efficient setup and opera- tion. The ByVision user interface operates within a Windows XP professional platform for speed and net- work compatibility.

The firm’s popular Bysoft CAD/CAM software has a new addition: the Plant Manager Cutting (PMC) module. It finds use for fact-based planning and monitoring of all waterjet- and laser-cutting process-

es. The PMC automatically processes order and CAD data independent of any pro- grammer intervention, eliminating the time required for cutting-plan preparation and feedback to the production-planning system. Managers gain access to criti- cal decision-making data including load balancing of each machine, order volume and status, and expected completion and due dates.

Bystronic Inc.: 847/214-0300; www.bystronicusa.com

High Speed, and Precise Positioning

Techni Waterjet, Lenexa, KS, recently debuted its Quantum NXT electric servo pump and its TJ4100-G-X3 gantry-style waterjet-cutting machine (below). The Quantum, explained company officials at FABTECH 2013 in Chicago, employs a

servo motor directly enveloping a high-load precision ball screw that houses the ceramic plungers. Pumping action results from the reciprocating plungers.

The TJ4100-G incorporates linear-scale feedback. By mapping the entire cut- ting area with a laser-calibrated digital encoder, the motion system is rated to a posi- tional accuracy of 0.0005 in.; cutting speed tops out at 1000 in./min.

Also on display at FABTECH: a rotary axis that employs a direct-drive motor assembly capable of accurately (±0.1 deg.) positioning and contouring a workpiece under the cutting stream.

Techni Waterjet: 888/832-4643; www.techniwaterjet.com

appears in an interactive window; gen- erating a 2D profile from any face or slice is just a click away. 3D pathing is just as easy, with the AutoPath function creating the tool path and applying the required attributes for 3D cutting before exporting.

Free to Omax machine owners, Intelli-Cam is part of the firm’s Intelli- Max software suite. “Job shops will ben- efit from Intelli-Cam since they will rarely ever again have to ask their cus- tomers to resave a file to a format they can accept, because now they can accept nearly all of them,” says Omax software architect Carl Olsen.”

Among the software’s standard features:

• Can run as a standalone applica- tion, or integrated into many popular 3D CAD systems;

• Supports a wide range of neutral and native 3D file formats, including CATIA, SolidWorks, ACIS, Inventor, Step, Siemens NX and more; and

• Offers single-click export to an Omax CAD file or open direct into Omax Intelli-Max Layout or Make.

Omax Corp.: 253/872-2300; www.omax.com

24 MetalForming/March 2014

www.metalformingmagazine.com

ERP

Order Manager

Part Manager CAD

Job Job Scheduler Assistant

Job Manager Machine Manager

Monitoring Event Handler