Page 15 - MetalForming January 2014

P. 15

Tech Update

The Edge X-5 features an industrial PC controller designed specifically for five-axis waterjet cutting. The AquaVision Di Con- troller’s open-architecture design gives operators the freedom to fine-tune programs from any CAD/CAM/nesting software, using standard G&M CNC code. Its Intelligent Work Envelope auto- matically adjusts depending on the angle of the cut to protect the operator, material and system components.

The Edge X-5, ballscrew-driven for optimal precision, features direct-couple AC brushless digital servo motors, single or double carriages, and cutting-table size from 5 by 5 to 24 by 13 ft.

Jet Edge, Inc.: 763/497-8700; www.jetedge.com

Five-Axis Fiber-Laser Cutting

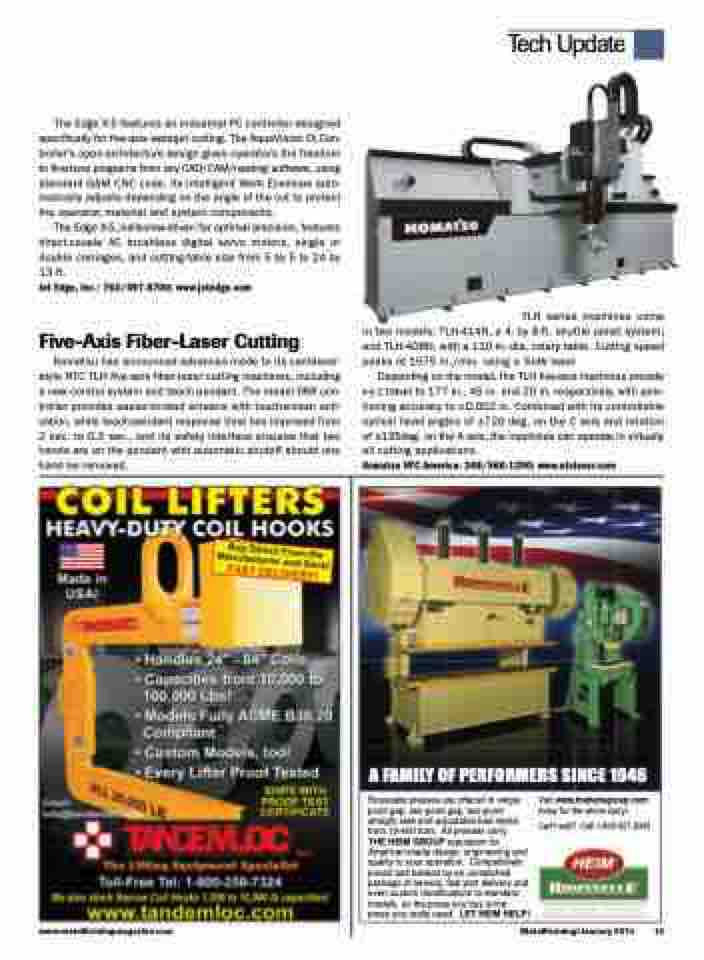

Komatsu has announced advances made to its cantilever- style NTC TLH five-axis fiber-laser cutting machines, including a new control system and teach pendant. The model 06R con- troller provides easier-to-read screens with touchscreen acti- vation, while teach-pendant response time has improved from 2 sec. to 0.5 sec., and its safety interface ensures that two hands are on the pendant with automatic shutoff should one hand be removed.

TLH series machines come in two models: TLH-414N, a 4- by 8-ft. shuttle pallet system; and TLH-408N, with a 110-in.-dia. rotary table. Cutting speed

peaks at 1575 in./min. using a 3-kW laser.

Depending on the model, the TLH five-axis machines provide

x-y-z travel to 177 in., 45 in. and 20 in. respectively, with posi- tioning accuracy to ±0.002 in. Combined with its controllable optical head angles of ±720 deg. on the C axis and rotation of ±135deg. on the A axis, the machines can operate in virtually all cutting applications.

Komatsu NTC America: 248/560-1200; www.ntclaser.com

A FAMILY OF PERFORMERS SINCE 1946

Rousselle presses are offered in single point gap, two-point gap, two-point straight side and adjustable bed styles from 15-400 tons. All presses carry

THE HEIM GROUP reputation for American-made design, engineering and quality to your operation. Competitively priced and backed by an unmatched package of service, fast part delivery and even custom modifications to standard models, so the press you buy is the press you really need. LET HEIM HELP!

Visit www.theheimgroup.com today for the whole story!

Can’t wait? Call 1-800-927-9393

www.metalformingmagazine.com

MetalForming/January 2014 13