Page 45 - MetalForming November 2013

P. 45

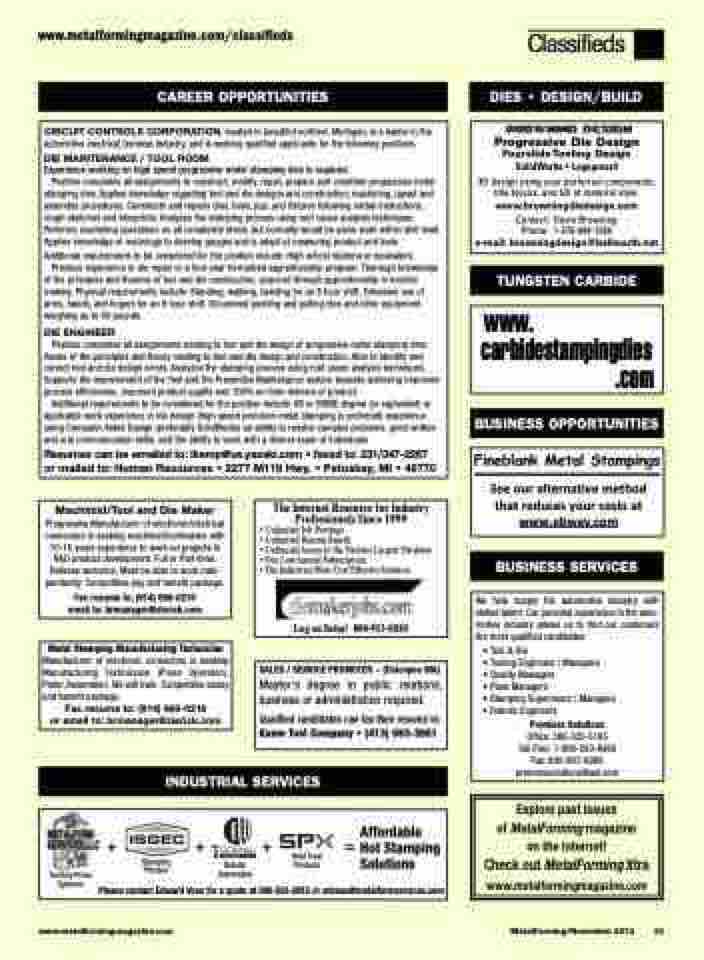

www.metalformingmagazine.com/classifieds

Classifieds

CAREER OPPORTUNITIES

DIES • DESIGN/BUILD

CIRCUIT CONTROLS CORPORATION, located in beautiful northern Michigan, is a leader in the automotive electrical terminal industry, and is seeking qualified applicants for the following positions. DIE MAINTENANCE / TOOL ROOM

Experience working on high speed progressive metal stamping dies is required.

Position completes all assignments to construct, modify, repair, prepare and condition progressive metal stamping dies. Applies knowledge regarding tool and die designs and construction, machining, layout and assembly procedures. Constructs and repairs dies, tools, jigs, and fixtures following verbal instructions, rough sketches and blueprints. Analyzes the stamping process using root cause analysis techniques. Performs machining operations on all complexity levels, but normally would be given work within skill level. Applies knowledge of metrology to develop gauges and is adept at measuring product and tools.

Additional requirements to be considered for the position include: High school diploma or equivalent. Previous experience in die repair or a four-year formalized apprenticeship program. Thorough knowledge

of the principles and theories of tool and die construction, acquired through apprenticeship in tool/die making. Physical requirements include: Standing, walking, bending for an 8 hour shift. Extensive use of arms, hands, and fingers for an 8 hour shift. Occasional pushing and pulling dies and other equipment weighing up to 50 pounds.

DIE ENGINEER

Position completes all assignments relating to tool and die design of progressive metal stamping dies. Aware of the principles and theory relating to tool and die design and construction. Able to identify and correct tool and die design errors. Analyzes the stamping process using root cause analysis techniques. Supports the improvement of the Tool and Die Preventive Maintenance system towards achieving improved process efficiencies, improved product quality and 100% on-time delivery of product.

Additional requirements to be considered for the position include: AS or BSME degree (or equivalent) or applicable work experience in die design (high speed precision metal stamping is preferred) experience using Computer Aided Design (preferably SolidWorks) an ability to resolve complex problems, good written and oral communication skills, and the ability to work with a diverse team of individuals.

Resumes can be emailed to: lkemp@us.yazaki.com • faxed to: 231/347-2267 or mailed to: Human Resources • 2277 M119 Hwy. • Petoskey, MI • 49770

TUNGSTEN CARBIDE

BUSINESS OPPORTUNITIES

BUSINESS SERVICES

See our alternative method that reduces your costs at www.ebway.com

Machinist/Tool and Die Maker

Progressive Manufacturer of electronic/electrical connectors is seeking machinist/toolmakers with 10-15 years experience to work on projects in R&D product development. Full or Part-time. Retirees welcome. Must be able to work inde- pendently. Competitive pay and benefit package. Fax resume to: (914) 666-0216

email to: hrmanager@zierick.com

We help supply the automotive industry with skilled talent. Our personal experience in the auto- motive industry allows us to find our customers the most qualified candidates.

• Tool & Die

• Tooling Engineers / Managers

• Quality Managers

• Plant Managers

• Stamping Supervisors / Managers • Robotic Engineers

Premiere Solutions

Office: 386-325-5165 Toll Free: 1-800-283-8960 Fax: 800-867-9989 premieresolutions@aol.com

Metal Stamping Manufacturing Technician

Manufacturer of electronic connectors is seeking Manufacturing Technicians (Press Operators, Plater, Assembler). We will train. Competitive salary and benefit package.

Fax resume to: (914) 666-0216

or email to: hrmanager@zierick.com

www.metalformingmagazine.com

MetalForming/November 2013 43

INDUSTRIAL SERVICES

SALES / SERVICE PROMOTER – (Chicopee MA)

Master's degree in public relations, business or administration required.

Qualified candidates can fax their resume to: Kame Tool Company • (413) 593-3951

Progressive Die Design FourslideTooling Design

SolidWorks • Logopress3

3D design using your preferred components, title blocks, and bill of material style. www.browningdiedesign.com Contact: Kevin Browning

Phone: 1-270-684-1050

e-mail: browningdesign@bellsouth.net

www. carbidestampingdies

.com

The Internet Resource for Industry Professionals Since 1999

• Unlimited Job Postings

• Unlimited Resume Search

• Unlimited Access to the Nations Largest Database • One Low Annual Subscription

• The Industries Most Cost Effective Solution

LogonToday! 800-913-0020

Explore past issues

of MetalForming magazine on the Internet!

Check out MetalForming Xtra www.metalformingmagazine.com

+

Affordable

+ + = Hot Stamping

Robotic Automation

Turnkey Press Systems

Please contact Edward Voss for a quote at 586 933-3815 or edvoss@metalformservices.com

Stamping Presses

Heat Treat

Products Solutions