Page 27 - MetalForming September 2013

P. 27

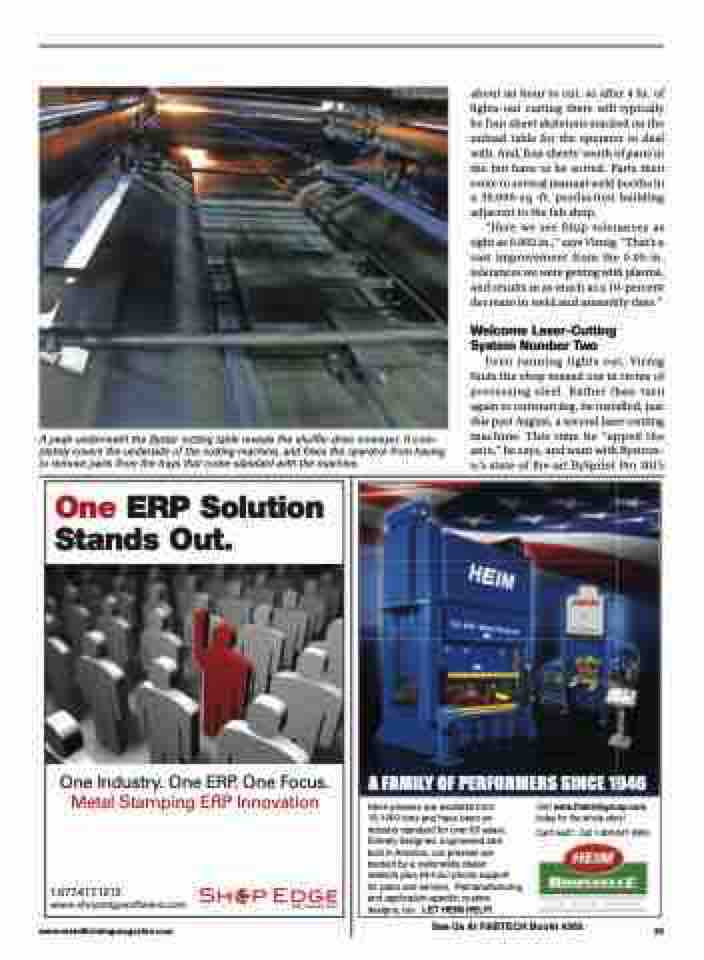

A peak underneath the Bystar cutting table reveals the shuffle-drive conveyor. It com- pletely covers the underside of the cutting machine, and frees the operator from having to remove parts from the trays that come standard with the machine.

about an hour to cut, so after 4 hr. of lights-out cutting there will typically be four sheet skeletons stacked on the unload table for the operator to deal with. And, four sheets’ worth of parts in the bin have to be sorted. Parts then route to several manual weld booths in a 30,000-sq.-ft. production building adjacent to the fab shop.

“Here we see fitup tolerances as tight as 0.002 in.,” says Virnig. “That’s a vast improvement from the 0.05-in. tolerances we were getting with plasma, and results in as much as a 10-percent decrease in weld and assembly time.”

Welcome Laser-Cutting System Number Two

Even running lights out, Virnig finds the shop maxed out in terms of processing steel. Rather than turn again to outsourcing, he installed, just this past August, a second laser-cutting machine. This time he “upped the ante,” he says, and went with Bystron- ic’s state-of the-art BySprint Pro 3015

One ERP Solution Stands Out.

A FAMILY OF PERFORMERS SINCE 1946

Heim presses are available from 15-1000 tons and have been an industry standard for over 65 years. Entirely designed, engineered and

built in America, our presses are backed by a nationwide dealer

network plus 24-hour phone support

for parts and service. Remanufacturing and application-specific custom designs, too. LET HEIM HELP!

Visit www.theheimgroup.com today for the whole story!

Can’t wait? Call 1-800-927-9393

One Industry. One ERP. One Focus.

Metal Stamping ERP Innovation

1.877.417.1212 www.shopedgesoftware.com

www.metalformingmagazine.com See Us At FABTECH Booth 4363 25