Page 24 - MetalForming August 2013

P. 24

Fabricators

Gain an Edge with Plasma-Arc Cutting

For fast and accurate plate beveling/weld prep and hole cutting, high- definition automated plasma-arc cutting kicks other fabricating processes, like shearing and punching, to the curb. Here we present two case studies where new automated cutting machines yielded exceptionally short ROIs.

BY BRAD F. KUVIN, EDITOR

Chances are good that unless you’ve studied up recently, you are not up to speed on the newly expanded capabilities of plasma-arc- cutting (PAC) technology. In talking recently with folks from two completely different types of metal-fabricating operations, who have indeed studied up on PAC technology, here’s some of

the feedback I received:

• “Manual cutting-machine setup

procedures to bevel plate edges, for weld prep for example, that used to take as long as 2 hr. per job have been completely eliminated thanks to automation.”

• “Using our new PAC technology to etch metal parts takes an 8-hr. job

down to just a few minutes.”

• “A set of jobs that took two weeks of

two-shift production to complete using our previous PAC machine now takes just one 8-hr. shift.”

• “Our customers love the quality of the holes we’re making in plates using our new PAC machine.”

• “We’re saving hundreds of hours leveraging new PAC technology, edge- beveling plate sections for weld prep.”

• “We recently completed a produc- tion job requiring 429 pierces. With- out newer technology, we could never have quoted such a

job.”

Who made these state-

ments? David Kerstet- ter, a manufacturing engineer at Schramm, Inc., an OEM manufac-

turer of hydraulic drill rigs; and Curt Renaud, founder and owner of Cur- tis Welding, a custom fabrica-

tion and welding shop.

Schramm Says So Long to Shearing, Punching

The Schramm drill-rig production facility in West Chester, PA, serves the 113-yr.-old company well, as it recent- ly received the 2013 Governor’s Impact

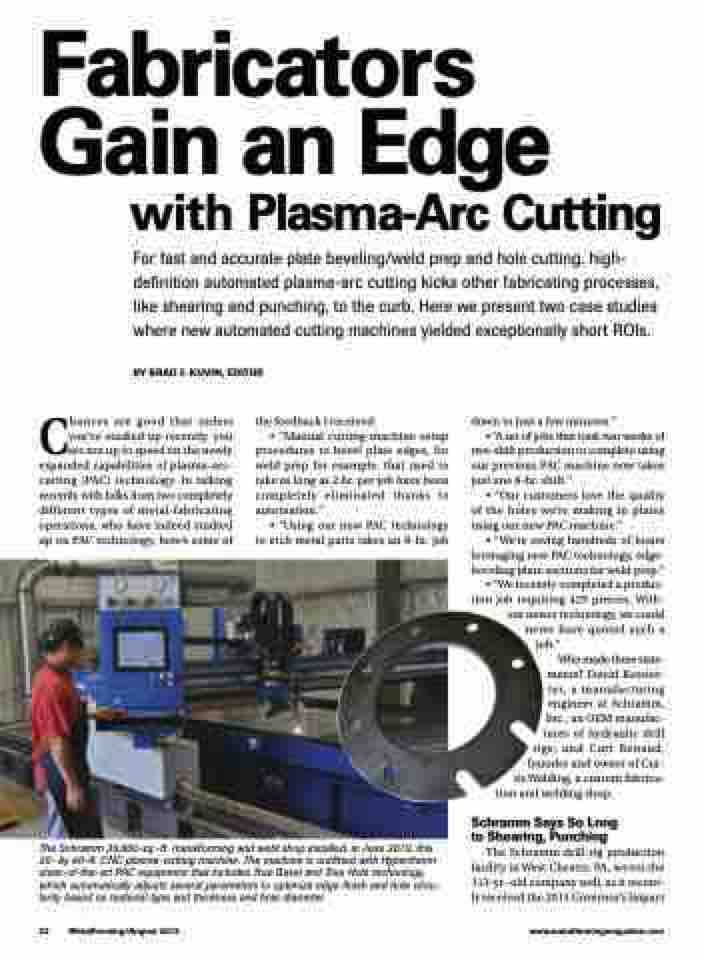

The Schramm 30,000-sq.-ft. metalforming and weld shop installed, in June 2010, this 20- by 40-ft. CNC plasma-cutting machine. The machine is outfitted with Hypertherm state-of-the-art PAC equipment that includes True Bevel and True Hole technology, which automatically adjusts several parameters to optimize edge finish and hole circu- larity based on material type and thickness and hole diameter.

22 MetalForming/August 2013

www.metalformingmagazine.com