Page 52 - MetalForming May 2013

P. 52

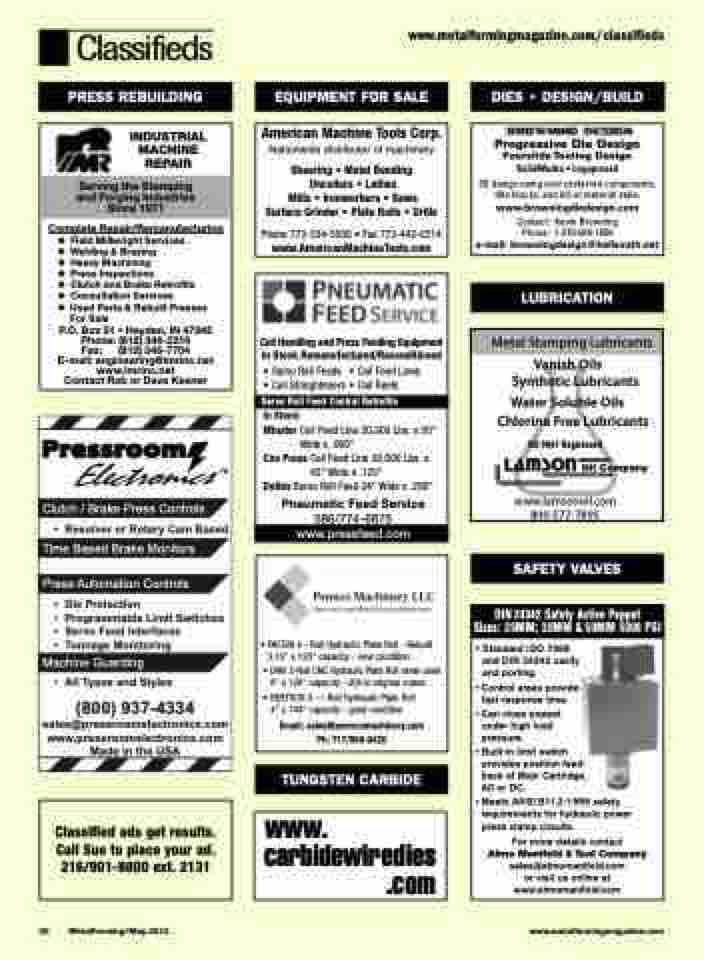

Classifieds

PRESS REBUILDING

www.metalformingmagazine.com/classifieds

EQUIPMENT FOR SALE

DIES • DESIGN/BUILD

INDUSTRIAL MACHINE REPAIR

Serving the Stamping and Forging Industries Since 1971

Complete Repair/Remanufacturing

N Field Millwright Services N Welding & Brazing

N Heavy Machining

N Press Inspections

N Clutch and Brake Retrofits

N Consultation Services

N Used Parts & Rebuilt Presses

For Sale

P.O. Box 51 • Hayden, IN 47245

Phone: (812) 346-2216

Fax: (812) 346-7704 E-mail: engineering@imrinc.net www.imrinc.net Contact Rob or Dave Keener

American Machine Tools Corp.

Nationwide distributor of machinery

Shearing • Metal Bending Uncoilers • Lathes Mills • Ironworkers • Saws

Surface Grinder • Plate Rolls • Drills

Phone 773-334-5000 • Fax 773-442-0314

www.AmericanMachineTools.com

Progressive Die Design FourslideTooling Design

SolidWorks • Logopress3

3D design using your preferred components, title blocks, and bill of material style. www.browningdiedesign.com Contact: Kevin Browning

Phone: 1-270-684-1050

e-mail: browningdesign@bellsouth.net

Coil Handling and Press Feeding Equipment In Stock Remanufactured/Reconditioned

• Servo Roll Feeds • Coil Feed Lines • Coil Straighteners • Coil Reels

Servo Roll Feed Control Retrofits

In Stock:

Minster Coil Feed Line 20,000 Lbs. x 50"

Wide x .060"

Coe Press Coil Feed Line 20,000 Lbs. x

42" Wide x .125"

Dallas Servo Roll Feed 24" Wide x .290"

Pneumatic Feed Service

586/774-6675

www.pressfeed.com

LUBRICATION

Metal Stamping Lubricants

Vanish Oils Synthetic Lubricants

Water Soluble Oils Chlorine Free Lubricants

ISO 9001 Registered

www.lamsonoil.com 800-577-7895

������ � ����� ����� ��������

� ������������������������

���� ����� ����� �������� ����� ���������� ��������

� �������������

� ������������������������� � �������������������

� �����������������

������� ��������

� �����������������

����� �������� ������������������������������ ���������������������������� ���� �� ��� ���

• FACCIN 4 - Roll Hydraulic Plate Roll - Rebuilt 3.15" x 120" capacity - new condition

• DAVI 3-Roll CNC Hydraulic Plate Roll never used 8" x 120" capacity - still in original crates

• BERTSCH 3 — Roll Hydraulic Plate Roll 4" x 144" capacity - good condition

Email: sales@penncomachinery.com Ph: 717/569-0420

SAFETY VALVES

DIN 24342 Safety Active Poppet Sizes: 25MM; 32MM & 50MM 5000 PSI

• Standard ISO 7368 and DIN 24342 cavity and porting.

• Control areas provide fast response time.

• Can close poppet under high load pressure.

• Built-in limit switch provides position feed- back of Main Cartridge, AC or DC.

• Meets ANSI B11.2-1995 safety requirements for hydraulic power press clamp circuits.

For more details contact

Almo Manifold & Tool Company

sales@almomanifold.com or visit us online at www.almomanifold.com

Classified ads get results. Call Sue to place your ad. 216/901-8800 ext. 2131

50 MetalForming/May 2013

www.metalformingmagazine.com

TUNGSTEN CARBIDE

www. carbidewiredies

.com