Page 55 - MetalForming March 2013

P. 55

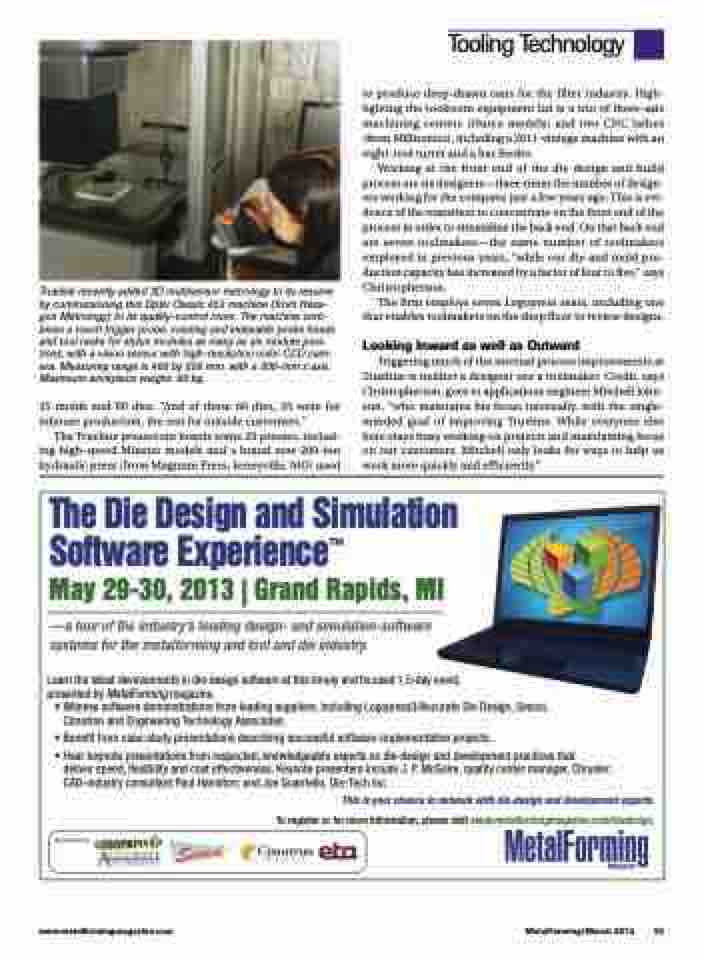

Trueline recently added 3D multisensor metrology to its resume by commissioning this Optiv Classic 453 machine (from Hexa- gon Metrology) to its quality-control room. The machine com- bines a touch trigger probe, rotating and indexable probe heads and tool racks for stylus modules as many as six module posi- tions, with a vision sensor with high-resolution color CCD cam- era. Measuring range is 400 by 500 mm, with a 300-mm z axis. Maximum workpiece weight: 60 kg.

35 molds and 60 dies. “And of those 60 dies, 35 were for inhouse production, the rest for outside customers.”

The Trueline pressroom boasts some 20 presses, includ- ing high-speed Minster models and a brand new 200-ton hydraulic press (from Magnum Press, Jerseyville, MO) used

to produce deep-drawn cans for the filter industry. High- lighting the toolroom equipment list is a trio of three-axis machining centers (Hurco models) and two CNC lathes (from Milltronics), including a 2011-vintage machine with an eight-tool turret and a bar feeder.

Working at the front end of the die design and build process are six designers—three times the number of design- ers working for the company just a few years ago. This is evi- dence of the transition to concentrate on the front end of the process in order to streamline the back end. On that back end are seven toolmakers—the same number of toolmakers employed in previous years, “while our die and mold pro- duction capacity has increased by a factor of four to five,” says Christopherson.

The firm employs seven Logopress seats, including one that enables toolmakers on the shop floor to review designs.

Looking Inward as well as Outward

Triggering much of the internal process improvements at Trueline is neither a designer nor a toolmaker. Credit, says Christopherson, goes to applications engineer Mitchell John- son, “who maintains his focus internally, with the single- minded goal of improving Trueline. While everyone else here stays busy working on projects and maintaining focus on our customers, Mitchell only looks for ways to help us work more quickly and efficiently.”

Tooling Technology

The Die Design and Simulation Software ExperienceTM

May 29-30, 2013 | Grand Rapids, MI

—a tour of the industry’s leading design- and simulation-software systems for the metalforming and tool and die industry.

Learn the latest developments in die-design software at this timely and focused 1.5-day event, presented by MetalForming magazine.

• Witness software demonstrations from leading suppliers, including Logopress3/Accurate Die Design, Sescoi, Cimatron and Engineering Technology Associates.

• Benefit from case-study presentations describing successful software-implementation projects.

• Hear keynote presentations from respected, knowledgeable experts on die-design and development practices that

deliver speed, flexibility and cost effectiveness. Keynote presenters include J. P. McGuire, quality center manager, Chrysler; CAD-industry consultant Paul Hamilton; and Joe Guarriello, Die-Tech Inc.

Sponsored by:

This is your chance to network with die-design and development experts.

To register or for more information, please visit www.metalformingmagazine.com/diedesign.

www.metalformingmagazine.com

MetalForming/March 2013 53