Page 84 - MetalForming October 2012

P. 84

The Science of Forming

By Stuart Keeler

Advanced High Strength Steels Assist Stamping Weight Reduction

Tooling Technology

0.3

0.2

0.1

0

200 400 600 Engineering Yield Strength (MPa)

ble

Mild and HSLA Steel

Maximim Allowa n-Value

Minimum

Specified Yield Strength

Many industries are reduc- ing the weight of their stampings, especially automotive. In addition to weight reduction of the primary stamp- ing, secondary weight reductions occur in stampings that support the force or function of the pri- mary stamping. Reducing the weight of a vehicle body-in-white allows secondary weight reduc- tions in support axles, power transmissions and other areas of the vehicle.

A structural engineer directed

to reduce the weight of a load-

bearing stamping will learn from

his textbook that load capacity

equals material strength multi-

plied by the cross-sectional area

being loaded. Therefore, an

increase in strength can compensate for the desired reduc- tion in sheet thickness to provide a constant load-carrying capacity.

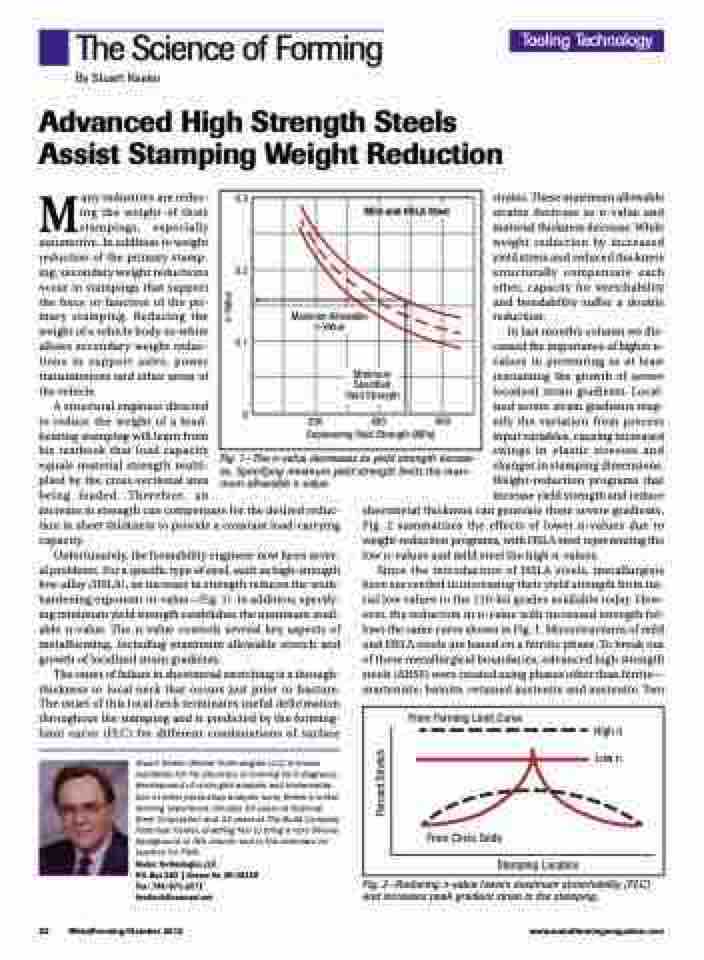

Unfortunately, the formability engineer now faces sever- al problems. For a specific type of steel, such as high-strength low-alloy (HSLA), an increase in strength reduces the work- hardening exponent (n-value—Fig. 1). In addition, specify- ing minimum yield strength establishes the maximum avail- able n-value. The n-value controls several key aspects of metalforming, including maximum allowable stretch and growth of localized strain gradients.

The onset of failure in sheetmetal stretching is a through- thickness or local neck that occurs just prior to fracture. The onset of this local neck terminates useful deformation throughout the stamping and is predicted by the forming- limit curve (FLC) for different combinations of surface

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementa- tion of other press-shop analysis tools. Keeler’s metal- forming experience includes 24 years at National Steel Corporation and 12 years at The Budd Company Technical Center, enabling him to bring a very diverse background to this column and to the seminars he teaches for PMA.

Keeler Technologies LLC

P.O. Box 283 | Grosse Ile, MI 48138 Fax: 734/671-2271 keeltech@comcast.net

strains. These maximum allowable strains decrease as n-value and material thickness decrease. While weight reduction by increased yield stress and reduced thickness structurally compensate each other, capacity for stretchability and bendability suffer a double reduction.

In last month’s column we dis- cussed the importance of higher n- values in preventing or at least restraining the growth of severe localized strain gradients. Local- ized severe strain gradients mag- nify the variation from process input variables, causing increased swings in elastic stresses and changes in stamping dimensions. Weight-reduction programs that increase yield strength and reduce

sheetmetal thickness can generate these severe gradients. Fig. 2 summarizes the effects of lower n-values due to weight-reduction programs, with HSLA steel representing the low n-values and mild steel the high n-values.

Since the introduction of HSLA steels, metallurgists have succeeded in increasing their yield strength from ini- tial low values to the 110-ksi grades available today. How- ever, the reduction in n-value with increased strength fol- lows the same curve shown in Fig. 1. Microstructures of mild and HSLA steels are based on a ferritic phase. To break out of these metallurgical boundaries, advanced high strength steels (AHSS) were created using phases other than ferrite— martensite, bainite, retained austenite and austenite. Two

Fig. 1—The n-value decreases as yield strength increas- es. Specifying minimum yield strength limits the maxi- mum allowable n-value.

From Forming Limit Curve

High n Low n

From Circle Grids

Stamping Location

82 MetalForming/October 2012

www.metalformingmagazine.com

Fig. 2—Reducing n-value lowers maximum stretchability (FLC) and increases peak gradient strain in the stamping.

Percent Stretch

n-Value