Page 74 - MetalForming October 2012

P. 74

Hybrid Robotic-

Welding Gun

Adds to Automation Benefits

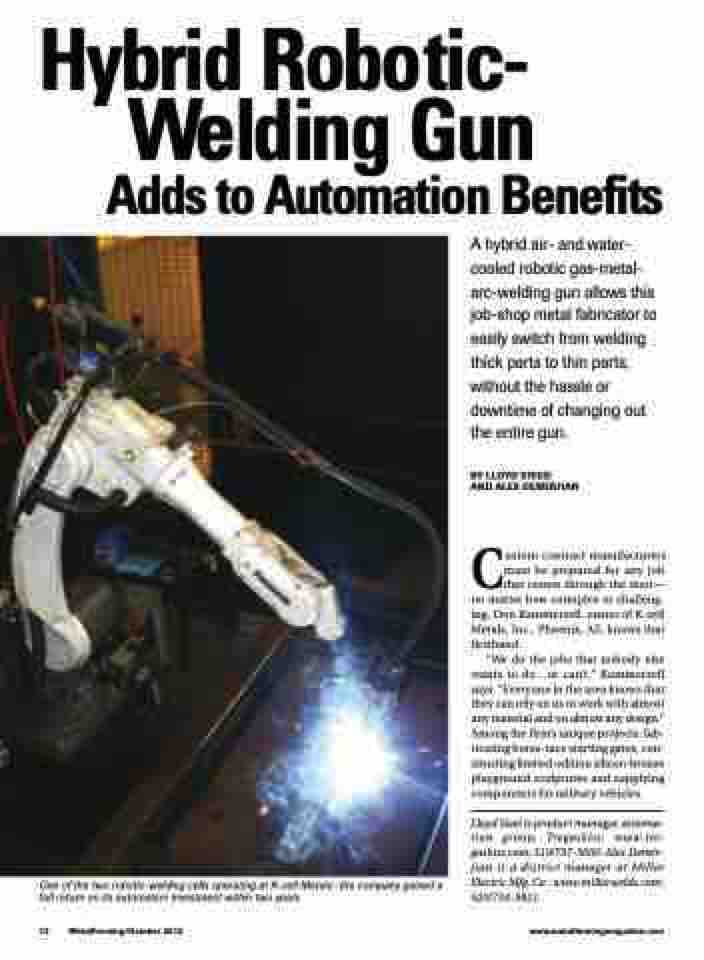

One of the two robotic-welding cells operating at K-zell Metals—the company gained a full return on its automation investment within two years.

A hybrid air- and water- cooled robotic gas-metal- arc-welding gun allows this job-shop metal fabricator to easily switch from welding thick parts to thin parts, without the hassle or downtime of changing out the entire gun.

BY LLOYD STEED

AND ALEX DEMIRJIAN

Custom contract manufacturers must be prepared for any job that comes through the door— no matter how comtplex or challeng- ing. Don Kammerzell, owner of K-zell Metals, Inc., Phoenix, AZ, knows that firsthand.

“We do the jobs that nobody else wants to do...or can’t,” Kammerzell says. “Everyone in the area knows that they can rely on us to work with almost any material and on almost any design.” Among the firm’s unique projects: fab- ricating horse-race starting gates, con- structing limited-edition silicon-bronze playground sculptures and supplying components for military vehicles.

Lloyd Steel is product manager, automa- tion group, Tregaskiss: www.tre- gaskiss.com; 519/737-3000. Alex Demir- jian is a district manager at Miller Electric Mfg. Co.: www.millerwelds.com; 920/734-9821.

72 MetalForming/October 2012

www.metalformingmagazine.com