Page 36 - MetalForming September 2012

P. 36

Is It Time to Purchase a New ERP System?

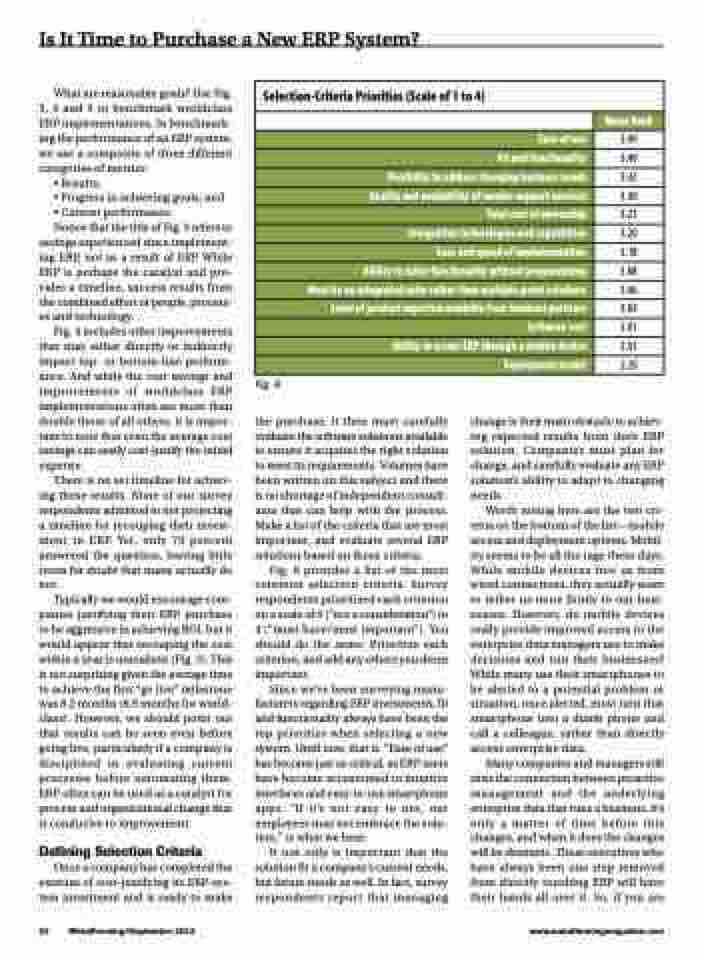

Selection-Criteria Priorities (Scale of 1 to 4)

Mean Rank

Ease of use

3.49

Fit and functionality

3.49

Flexibility to address changing business needs

3.42

Quality and availability of vendor-support services

3.30

Total cost of ownership

3.21

Integration technologies and capabilities

3.20

Ease and speed of implementation

3.18

Ability to tailor functionality without programming

3.08

Must be an integrated suite rather than multiple-point solutions

3.06

Level of product expertise available from business partners

3.02

Software cost

3.01

Ability to access ERP through a mobile device

2.31

Deployment model

2.29

What are reasonable goals? Use Fig. 3, 4 and 5 to benchmark worldclass ERP implementations. In benchmark- ing the performance of an ERP system, we use a composite of three different categories of metrics:

• Results;

• Progress in achieving goals; and

• Current performance.

Notice that the title of Fig. 3 refers to

savings experienced since implement- ing ERP, not as a result of ERP. While ERP is perhaps the catalyst and pro- vides a timeline, success results from the combined effort of people, process- es and technology.

Fig. 4 includes other improvements that may either directly or indirectly impact top- or bottom-line perform- ance. And while the cost savings and improvements of worldclass ERP implementations often are more than double those of all others, it is impor- tant to note that even the average cost savings can easily cost-justify the initial expense.

There is no set timeline for achiev- ing these results. None of our survey respondents admitted to not projecting a timeline for recouping their invest- ment in ERP. Yet, only 70 percent answered the question, leaving little room for doubt that many actually do not.

Typically we would encourage com- panies justifying their ERP purchase to be aggressive in achieving ROI, but it would appear that recouping the cost within a year is unrealistic (Fig. 5). This is not surprising given the average time to achieve the first “go live” milestone was 8.2 months (6.9 months for world- class). However, we should point out that results can be seen even before going live, particularly if a company is disciplined in evaluating current processes before automating them. ERP often can be used as a catalyst for process and organizational change that is conducive to improvement.

Defining Selection Criteria

Once a company has completed the exercise of cost-justifying its ERP-sys- tem investment and is ready to make

Fig. 6

the purchase, it then must carefully evaluate the software solutions available to ensure it acquires the right solution to meet its requirements. Volumes have been written on this subject and there is no shortage of independent consult- ants that can help with the process. Make a list of the criteria that are most important, and evaluate several ERP solutions based on those criteria.

Fig. 6 provides a list of the most common selection criteria. Survey respondents prioritized each criterion on a scale of 0 (“not a consideration”) to 4 (“must have/most important”). You should do the same: Prioritize each criterion, and add any others you deem important.

Since we’ve been surveying manu- facturers regarding ERP investments, fit and functionality always have been the top priorities when selecting a new system. Until now, that is. “Ease of use” has become just as critical, as ERP users have become accustomed to intuitive interfaces and easy-to-use smartphone apps. “If it’s not easy to use, our employees may not embrace the solu- tion,” is what we hear.

It not only is important that the solution fit a company’s current needs, but future needs as well. In fact, survey respondents report that managing

change is their main obstacle to achiev- ing expected results from their ERP solution. Companies must plan for change, and carefully evaluate any ERP solution’s ability to adapt to changing needs.

Worth noting here are the two cri- teria on the bottom of the list—mobile access and deployment options. Mobil- ity seems to be all the rage these days. While mobile devices free us from wired connections, they actually seem to tether us more firmly to our busi- nesses. However, do mobile devices really provide improved access to the enterprise data managers use to make decisions and run their businesses? While many use their smartphones to be alerted to a potential problem or situation, once alerted, most turn that smartphone into a dumb phone and call a colleague, rather than directly access enterprise data.

Many companies and managers still miss the connection between proactive management and the underlying enterprise data that runs a business. It’s only a matter of time before this changes, and when it does the changes will be dramatic. Those executives who have always been one step removed from directly touching ERP will have their hands all over it. So, if you are

34 MetalForming/September 2012

www.metalformingmagazine.com