Page 63 - MetalForming July 2012

P. 63

Tooling Technology

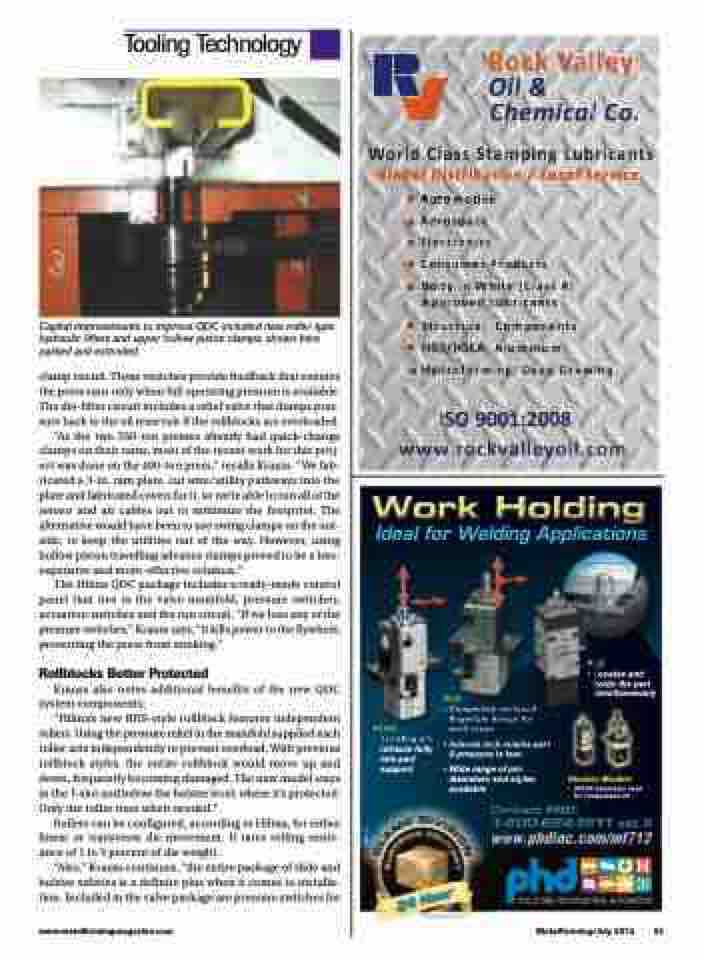

Capital improvements to improve QDC included new roller-type hydraulic lifters and upper hollow piston clamps, shown here parked and extended.

clamp circuit. These switches provide feedback that ensures the press runs only when full operating pressure is available. The die-lifter circuit includes a relief valve that dumps pres- sure back to the oil reservoir if the rollblocks are overloaded.

“As the two 550-ton presses already had quick-change clamps on their rams, most of the recent work for this proj- ect was done on the 400-ton press,” recalls Krauss. “We fab- ricated a 3-in. ram plate, cut wire/utility pathways into the plate and fabricated covers for it, so we’re able to run all of the sensor and air cables out to minimize the footprint. The alternative would have been to use swing clamps on the out- side, to keep the utilities out of the way. However, using hollow piston travelling advance clamps proved to be a less- expensive and more-effective solution.”

The Hilma QDC package includes a ready-made control panel that ties in the valve manifold, pressure switches, actuation switches and the run circuit. “If we lose any of the pressure switches,” Krauss says, “it kills power to the flywheel, preventing the press from stroking.”

Rollblocks Better Protected

Krauss also notes additional benefits of the new QDC system components:

“Hilma’s new RHS-style rollblock features independent rollers. Using the pressure relief in the manifold supplied each roller acts independently to prevent overload. With previous rollblock styles, the entire rollblock would move up and down, frequently becoming damaged. The new model stays in the T-slot and below the bolster level, where it’s protected. Only the roller rises when needed.”

Rollers can be configured, according to Hilma, for either linear or transverse die movement. It rates rolling resist- ance of 1 to 3 percent of die weight.

“Also,” Krauss continues, “the entire package of slide and bolster safeties is a definite plus when it comes to installa- tion. Included in the valve package are pressure switches for

Rock Valley Oil & Chemical Co.

World Class Stamping Lubricants Global Distribu on / Local Service

Automo ve

Aerospace

Electronics

Consumer Products

Body in White (Class A) Approved Lubricants

Structural Components HSS/HSLA, Aluminum Hydroforming, Deep Drawing

ISO 9001:2008 www.rockvalleyoil.com

Ideal for Welding Applications

MF712

www.metalformingmagazine.com

MetalForming/July 2012 61

PLKD

� �������� ��� �������� ����� ���� ���� �������

PLK

� ���������� �������� ��������� ������ ��� ���� �����

� �������� ���� ������� ���� �� �������� �� ����

� ���� ����� �� ��� ��������� ��� ������ ���������

���

� ������� ��� ����� ��� ���� ��������������

�������� ������

� ������������������� ��� ���������� ���

Contact PHD: 1-800-624-8511 ext.5

www.phdinc.com/mf712