Page 22 - MetalForming July 2012

P. 22

Press Pneumatic

Counterbalances

...are used to offset or counterbalance the weight of the press slide and upper die. Press manufacturers designed these adjustable systems to prolong bearing and gear life, provide smooth operation and reduce motor surge currents in the upstroke of the press.

BY DAVID ALKIRE SMITH

Metalformers must take care to correctly adjust press counter- balance, in order to ensure efficient and safe press operation. Air counterbalance systems:

• Are easily adjusted;

• Have large coun- terbalancing capacity;

• Have counterbal- ancing action that usu- ally varies less than 20 percent throughout the press stroke; and

• Reduce heat and electrical losses in the motor.

Air Counterbalance Function

Air counterbalance cylinders mount to the press housing and connect to the press slide. The minimum air pres- sure required in the counterbalance cylinders is that required to counter- balance the slide without a die in the press. This permits the press to be inched for maintenance allows the

David Alkire Smith, a tool engineer with more than 50 years of experience, is the editor of the Die Design Handbook and other engineering reference works; dsmith@smithassoc.com, www.smithas- soc.com.

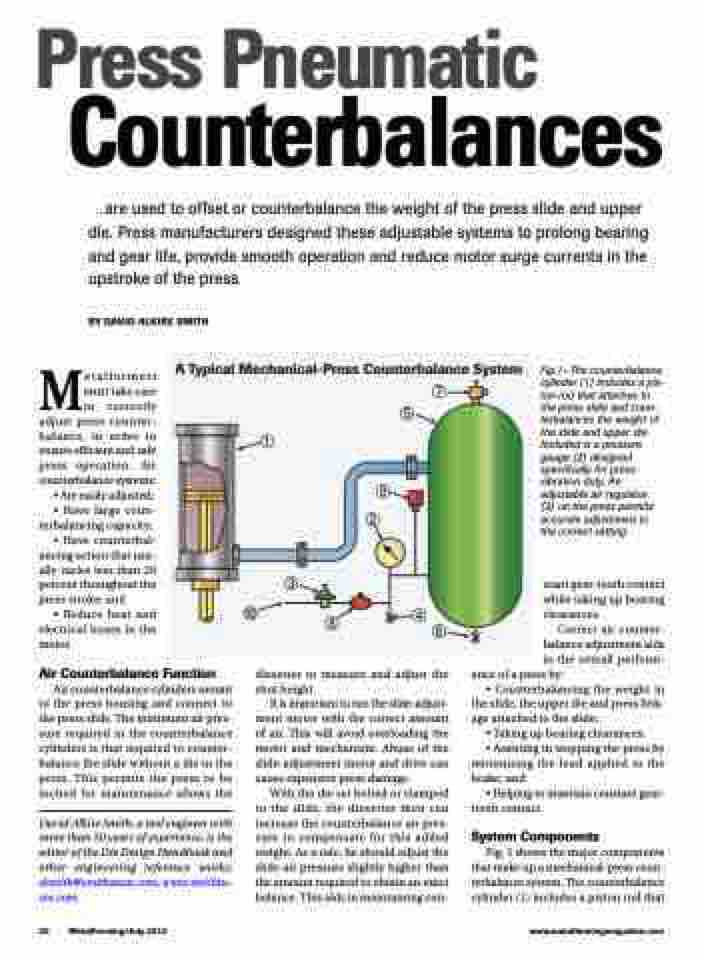

Fig.1—The counterbalance cylinder (1) includes a pis- ton rod that attaches to the press slide and coun- terbalances the weight of the slide and upper die. Included is a pressure gauge (2) designed specifically for press- vibration duty. An adjustable air regulator (3) on the press permits accurate adjustment to the correct setting.

stant gear-tooth contact while taking up bearing clearances.

Correct air counter- balance adjustment aids in the overall perform-

ance of a press by:

• Counterbalancing the weight in

the slide, the upper die and press link- age attached to the slide;

• Taking up bearing clearances;

• Assisting in stopping the press by minimizing the load applied to the brake; and

• Helping to maintain constant gear- tooth contact.

System Components

Fig. 1 shows the major components that make up a mechanical-press coun- terbalance system. The counterbalance cylinder (1) includes a piston rod that

A Typical Mechanical-Press Counterbalance System

diesetter to measure and adjust the shut height.

It is important to run the slide-adjust- ment motor with the correct amount of air. This will avoid overloading the motor and mechanism. Abuse of the slide-adjustment motor and drive can cause expensive press damage.

With the die set bolted or clamped to the slide, the diesetter then can increase the counterbalance air pres- sure to compensate for this added weight. As a rule, he should adjust the slide air pressure slightly higher than the amount required to obtain an exact balance. This aids in maintaining con-

20 MetalForming/July 2012

www.metalformingmagazine.com