Page 48 - MetalForming June 2012

P. 48

Tooling Technology

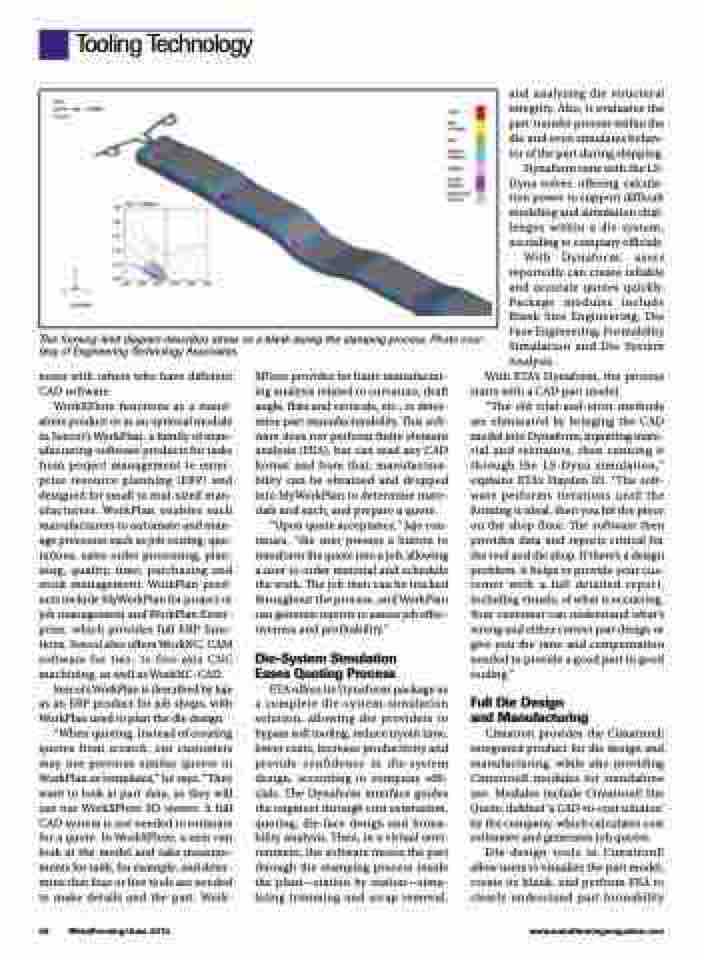

This forming-limit diagram describes stress on a blank during the stamping process. Photo cour- tesy of Engineering Technology Associates.

and analyzing die structural integrity. Also, it evaluates the part-transfer process within the die and even simulates behav- ior of the part during shipping.

Dynaform runs with the LS- Dyna solver, offering calcula- tion power to support difficult modeling and simulation chal- lenges within a die system, according to company officials.

With Dynaform, users reportedly can create reliable and accurate quotes quickly. Package modules include Blank Size Engineering, Die Face Engineering, Formability Simulation and Die System Analysis.

notes with others who have different CAD software.

WorkXPlore functions as a stand- alone product or as an optional module in Sescoi’s WorkPlan, a family of man- ufacturing-software products for tasks from project management to enter- prise resource planning (ERP) and designed for small to mid-sized man- ufacturers. WorkPlan enables such manufacturers to automate and man- age processes such as job costing, quo- tations, sales-order processing, plan- ning, quality, time, purchasing and stock management. WorkPlan prod- ucts include MyWorkPlan for project or job management and WorkPlan Enter- prise, which provides full ERP func- tions. Sescoi also offers WorkNC, CAM software for two- to five-axis CNC machining, as well as WorkNC-CAD.

Sescoi’s WorkPlan is described by Jaje as an ERP product for job shops, with WorkPlan used to plan the die design.

“When quoting, instead of creating quotes from scratch, our customers may use previous similar quotes in WorkPlan as templates,” he says. “They want to look at part data, so they will use our WorkXPlore 3D viewer. A full CAD system is not needed to estimate for a quote. In WorkXPlore, a user can look at the model and take measure- ments for radii, for example, and deter- mine that four or five tools are needed to make details and the part. Work-

XPlore provides for basic manufactur- ing analysis related to curvature, draft angle, flats and verticals, etc., to deter- mine part manufacturability. This soft- ware does not perform finite element analysis (FEA), but can read any CAD format and from that, manufactura- bility can be obtained and dropped into MyWorkPlan to determine mate- rials and such, and prepare a quote.

“Upon quote acceptance,” Jaje con- tinues, “the user presses a button to transform the quote into a job, allowing a user to order material and schedule the work. The job then can be tracked throughout the process, and WorkPlan can generate reports to assess job effec- tiveness and profitability.”

Die-System Simulation Eases Quoting Process

ETA offers its Dynaform package as a complete die-system-simulation solution, allowing die providers to bypass soft tooling, reduce tryout time, lower costs, increase productivity and provide confidence in die-system design, according to company offi- cials. The Dynaform interface guides the engineer through cost estimation, quoting, die-face design and forma- bility analysis. Then, in a virtual envi- ronment, the software moves the part through the stamping process inside the plant—station by station—simu- lating trimming and scrap removal,

With ETA’s Dynaform, the process starts with a CAD part model.

“The old trial-and-error methods are eliminated by bringing the CAD model into Dynaform, inputting mate- rial and restraints, then running it through the LS-Dyna simulation,” explains ETA’s Hayden III. “The soft- ware performs iterations until the forming is ideal, then you hit the piece on the shop floor. The software then provides data and reports critical for the tool and die shop. If there’s a design problem, it helps to provide your cus- tomer with a full detailed report, including visuals, of what is occurring. Your customer can understand what’s wrong and either correct part design or give you the time and compensation needed to provide a good part in good tooling.”

Full Die Design and Manufacturing

Cimatron provides the CimatronE integrated product for die design and manufacturing, while also providing CimatronE modules for standalone use. Modules include CimatronE Die Quote, dubbed ‘a CAD-to-cost solution’ by the company, which calculates cost estimates and generates job quotes.

Die-design tools in CimatronE allow users to visualize the part model, create its blank, and perform FEA to clearly understand part formability

46 MetalForming/June 2012

www.metalformingmagazine.com