Page 16 - MetalForming March 2011

P. 16

Best Practices

By Bob Dobrowsky

The Link Between Total Cost of Quality and Profitability

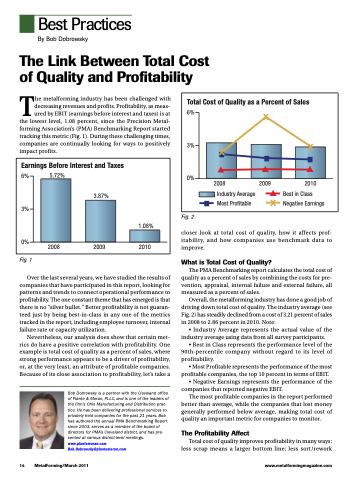

Total Cost of Quality as a Percent of Sales

6%

3%

0%

X

X

2008 2009 2010

X

Industry Average Most Profitable

Best in Class

X Negative Earnings

The metalforming industry has been challenged with decreasing revenues and profits. Profitability, as meas- ured by EBIT (earnings before interest and taxes) is at the lowest level, 1.08 percent, since the Precision Metal- forming Association’s (PMA) Benchmarking Report started tracking this metric (Fig. 1). During these challenging times, companies are continually looking for ways to positively impact profits.

Earnings Before Interest and Taxes

6%

3%

0%

5.72%

3.87%

1.08% 2008 2009 2010

Fig. 1

Over the last several years, we have studied the results of companies that have participated in this report, looking for patterns and trends to connect operational performance to profitability. The one constant theme that has emerged is that there is no “silver bullet.” Better profitability is not guaran- teed just by being best-in-class in any one of the metrics tracked in the report, including employee turnover, internal failure rate or capacity utilization.

Nevertheless, our analysis does show that certain met- rics do have a positive correlation with profitability. One example is total cost of quality as a percent of sales, where strong performance appears to be a driver of profitability, or, at the very least, an attribute of profitable companies. Because of its close association to profitability, let’s take a

Bob Dobrowsky is a partner with the Cleveland office of Plante & Moran, PLLC, and is one of the leaders of the firm’s Ohio Manufacturing and Distribution prac- tice. He has been delivering professional services to privately held companies for the past 21 years. Bob has authored the annual PMA Benchmarking Report since 2003, serves as a member of the board of directors for PMA’s Cleveland district, and has pre- sented at various district-level meetings. www.plantemoran.com

Bob.Dobrowsky@plantemoran.com

Fig. 2

closer look at total cost of quality, how it affects prof- itability, and how companies use benchmark data to improve.

What is Total Cost of Quality?

The PMA Benchmarking report calculates the total cost of quality as a percent of sales by combining the costs for pre- vention, appraisal, internal failure and external failure, all measured as a percent of sales.

Overall, the metalforming industry has done a good job of driving down total cost of quality. The industry average (see Fig. 2) has steadily declined from a cost of 3.21 percent of sales in 2008 to 2.86 percent in 2010. Note:

• Industry Average represents the actual value of the industry average using data from all survey participants.

• Best in Class represents the performance level of the 90th-percentile company without regard to its level of profitability.

• Most Profitable represents the performance of the most profitable companies, the top 10 percent in terms of EBIT.

• Negative Earnings represents the performance of the companies that reported negative EBIT.

The most profitable companies in the report performed better than average, while the companies that lost money generally performed below average, making total cost of quality an important metric for companies to monitor.

The Profitability Affect

Total cost of quality improves profitability in many ways: less scrap means a larger bottom line; less sort/rework

14 MetalForming/March 2011

www.metalformingmagazine.com