Page 30 - MetalForming April 2010

P. 30

Tooling Technology TOOLING BY DESIGN

PETER ULINTZ

Peter Ulintz has worked in the sheetmetal-forming industry since 1978. His background includes tool and die making, tool and process engineering, engineering management and product devel- opment. Peter also operates the website ToolingbyDesign.com, a source for the transfer of modern metalforming and tool-and-die technology, and which promotes the use of “Performance-Based Die Engineering Strategies.”

Peter speaks at PMA seminars and roundtables focusing on tool and die design, die maintenance, deep drawing, stamping simula- tion, tooling for stamping high- strength steels and problem solv- ing in the press shop.

Peter Ulintz pete.ulintz@toolingbydesign.com www.toolingbydesign.com

Question: We are designing a com- bination blank and draw die. This is not the first time we have designed and built a die like this, but I believe we have not been using the right formulas in the past to calculate press tonnage. On several occasions we had to move our dies to a larger press because the press we selected did not have enough power. In fact, the press slowed down noticeably during production. When we moved the die to a larger ton- nage press the problem went away. Both are mechanical presses.

I don’t want to repeat the same mis- take so I was hoping you could recom- mend the correct formula(s) we should be using for our tonnage calculations.

A: When a mechanical stamping press slows down during continuous operation, the problem usually lies with press energy, not press tonnage. How- ever, deep

drawing in

mechanical

presses presents

unique prob-

lems related to

press tonnage,

so we’ll need to

address both.

I will address

press tonnage

issues in this

month’s col-

umn and press

energy next

month.

The ton- nage rating of a press is the maximum load that can

be exerted in continuous operation without causing damage to the machine structure or to its drive system. But it is important to realize that the force avail- able to carry out work (blanking, draw- ing, forming, etc.) decreases in mechan- ical presses as the working distance above the bottom of the press stroke increases. This occurs because the lever- arm angle—the relationship between the crankshaft angle and the pitman— has reduced mechanical advantage high- er up in the stroke. This is commonly referred to as “derated tonnage.”

Before we can address derated ton- nage issues, we need to ensure that your blanking and drawing tonnage calcula- tion methods are valid. The two for- mulas you supplied to me were:

Blanking = blank thickness x tensile strength x blank circumference/2000

Drawing = blank thickness x yield

Combination Blanking and Drawing

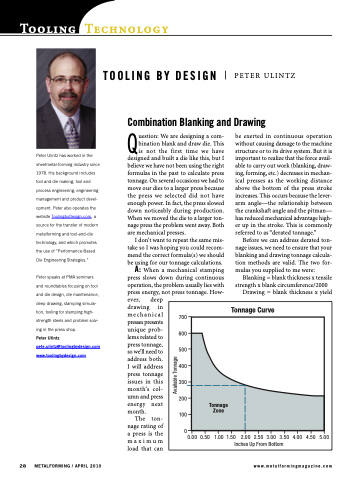

700 600 500 400 300 200 100

Tonnage Curve

Tonnage Zone

0

0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00

Inches Up From Bottom

28 METALFORMING / APRIL 2010

www.metalformingmagazine.com

Available Tonnage