Page 25 - MetalForming January 2010

P. 25

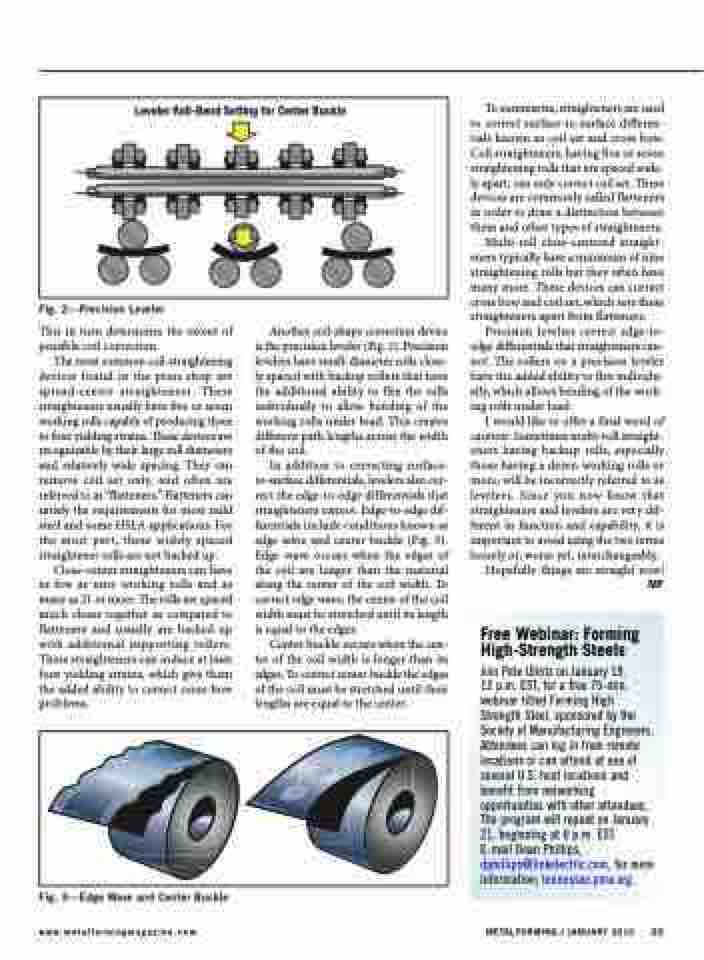

Leveler Roll-Bend Setting for Center Buckle

Fig. 2—Precision Leveler

This in turn determines the extent of possible coil correction.

The most common coil-straightening devices found in the press shop are spread-center straighteners. These straighteners usually have five or seven working rolls capable of producing three to four yielding strains. These devices are recognizable by their large roll diameters and relatively wide spacing. They can remove coil set only, and often are referred to as “flatteners.” Flatteners can satisfy the requirements for most mild steel and some HSLA applications. For the most part, these widely spaced straightener rolls are not backed up.

Close-center straighteners can have as few as nine working rolls and as many as 21 or more. The rolls are spaced much closer together as compared to flatteners and usually are backed up with additional supporting rollers. These straighteners can induce at least four yielding strains, which give them the added ability to correct cross-bow problems.

Fig. 3—Edge Wave and Center Buckle

Another coil-shape correction device is the precision leveler (Fig. 2). Precision levelers have small-diameter rolls close- ly spaced with backup rollers that have the additional ability to flex the rolls individually to allow bending of the working rolls under load. This creates different path lengths across the width of the coil.

In addition to correcting surface- to-surface differentials, levelers also cor- rect the edge-to-edge differentials that straighteners cannot. Edge-to-edge dif- ferentials include conditions known as edge wave and center buckle (Fig. 3). Edge wave occurs when the edges of the coil are longer than the material along the center of the coil width. To correct edge wave, the center of the coil width must be stretched until its length is equal to the edges.

Center buckle occurs when the cen- ter of the coil width is longer than its edges. To correct center buckle the edges of the coil must be stretched until their lengths are equal to the center.

To summarize, straighteners are used to correct surface-to-surface differen- tials known as coil set and cross bow. Coil straighteners, having five or seven straightening rolls that are spaced wide- ly apart, can only correct coil set. These devices are commonly called flatteners in order to draw a distinction between them and other types of straighteners.

Multi-roll close-centered straight- eners typically have a minimum of nine straightening rolls but they often have many more. These devices can correct cross bow and coil set, which sets these straighteners apart from flatteners.

Precision levelers correct edge-to- edge differentials that straighteners can- not. The rollers on a precision leveler have the added ability to flex individu- ally, which allows bending of the work- ing rolls under load.

I would like to offer a final word of caution: Sometimes multi-roll straight- eners having backup rolls, especially those having a dozen working rolls or more, will be incorrectly referred to as levelers. Since you now know that straighteners and levelers are very dif- ferent in function and capability, it is important to avoid using the two terms loosely or, worse yet, interchangeably.

Hopefully things are straight now!

MF

Free Webinar: Forming High-Strength Steels

Join Pete Ulintz on January 19,

12 p.m. EST, for a free 75-min. webinar titled Forming High Strength Steel, sponsored by the Society of Manufacturing Engineers. Attendees can log in from remote locations or can attend at one of several U.S. host locations and benefit from networking opportunities with other attendees. The program will repeat on January 21, beginning at 6 p.m. EST.

E-mail Dean Phillips, dphillips@linkelectric.com, for more information; tennessee.pma.org.

www.metalformingmagazine.com

METALFORMING / JANUARY 2010 23