Page 20 - MetalForming January 2010

P. 20

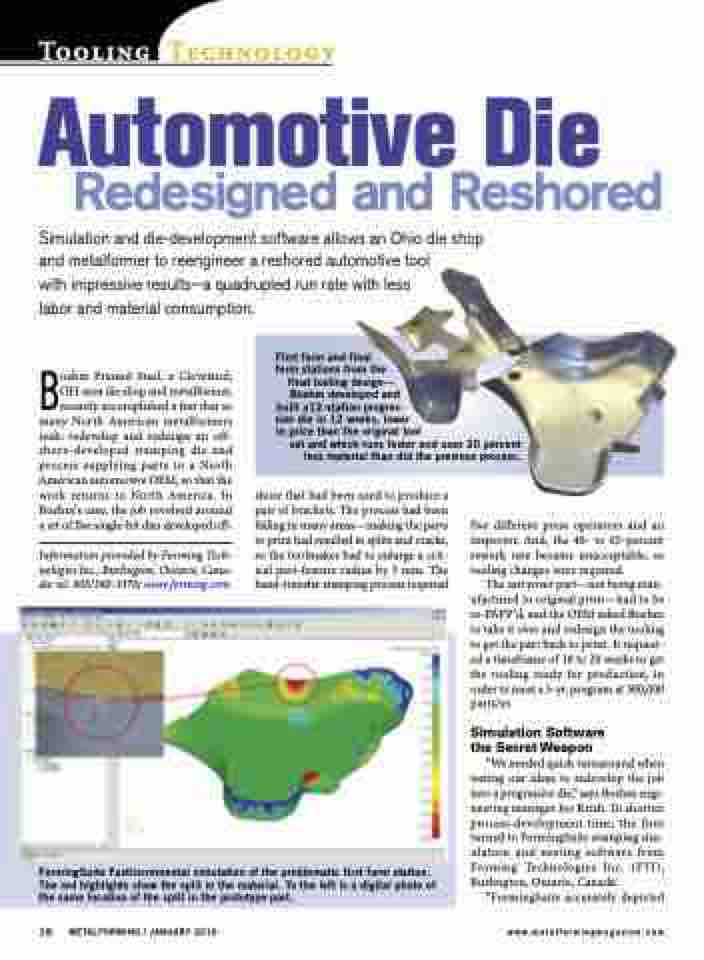

FormingSuite FastIncremental simulation of the problematic first form station. The red highlights show the split in the material. To the left is a digital photo of the same location of the split in the prototype part.

Tooling Technology

Automotive Die

Redesigned and Reshored

Simulation and die-development software allows an Ohio die shop and metalformer to reengineer a reshored automotive tool

with impressive results—a quadrupled run rate with less

labor and material consumption.

Boehm Pressed Steel, a Cleveland, OH-area die shop and metalformer, recently accomplished a feat that so many North American metalformers seek: redevelop and redesign an off- shore-developed stamping die and process supplying parts to a North American automotive OEM, so that the work returns to North America. In Boehm’s case, the job revolved around a set of five single-hit dies developed off-

Information provided by Forming Tech- nologies Inc., Burlington, Ontario, Cana- da: tel. 905/340-3370; www.forming.com.

First form and final form stations from the

final tooling design— Boehm developed and

built a12-station progres- sive die in 12 weeks, lower in price than the original tool

set and which runs faster and uses 20 percent less material than did the previous process.

shore that had been used to produce a pair of brackets. The process had been failing in many areas—making the parts to print had resulted in splits and cracks, so the toolmaker had to enlarge a crit- ical part-feature radius by 3 mm. The hand-transfer stamping process required

five different press operators and an inspector. And, the 40- to 65-percent rework rate became unacceptable, so tooling changes were required.

The carryover part—not being man- ufactured to original print—had to be re-PAPP’d, and the OEM asked Boehm to take it over and redesign the tooling to get the part back to print. It request- ed a timeframe of 18 to 20 weeks to get the tooling ready for production, in order to meet a 5-yr. program at 300,000 parts/yr.

Simulation Software the Secret Weapon

“We needed quick turnaround when testing our ideas to redevelop the job into a progressive die,” says Boehm engi- neering manager Joe Krish. To shorten process-development time, the firm turned to FormingSuite stamping sim- ulation and nesting software from Forming Technologies Inc. (FTI), Burlington, Ontario, Canada.

“FormingSuite accurately depicted

18 METALFORMING / JANUARY 2010

www.metalformingmagazine.com