Page 18 - MetalForming December 2009

P. 18

Cutting with Lasers and Waterjets

The Right Process at the Right Time

Today’s fabricators are looking for more than just speed. They need metal-fabricating equipment that will add capabilities and flexibility, enabling them to bring in new busi- ness. Dynamic applications in today’s hottest industries are using more inter- esting and unusual materials than ever before, and many metal fabricators are being called on to cut more exotic alloys, even composites. Among the tools of the trade: laser-cutting and waterjet-cut- ting systems.

Laser-cutting machines use a high- power laser beam to cut through sheet and plate.

Article submitted by Mitsubishi Laser and MC Machinery Systems, Inc., Wood Dale, IL: www.mitsubishi-world.com.

Twenty years ago, lasers were capable of cutting 1⁄2-in. steel at 1 to 2 in./min. Today, systems can cut 1⁄2-in. steel at 80 in./min. Automation, increased resonator power, and improvements in controllers have revolutionized the laser industry.

Lasers can quickly and easily switch from one metal alloy to the next with lit- tle downtime. Also, automation equip- ment helps fabricators achieve lean man-

ufacturing by increasing output while decreasing or eliminating labor costs.

Waterjet cutting represents one of the fastest-growing technologies used in the metal-fabrication industry. The process uses a high-pressure stream of water, with an added abrasive such as garnet, to make the cut. No heat is gen- erated during waterjet cutting, elimi- nating the risk of material distortion.

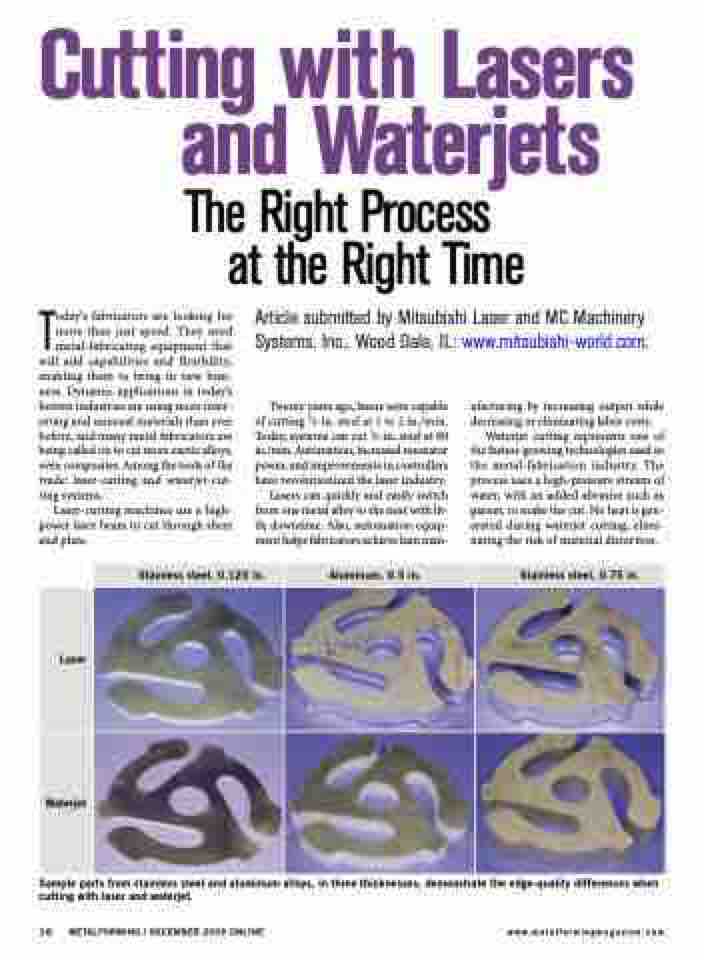

Stainless steel, 0.125 in.

Aluminum, 0.5 in.

Stainless steel, 0.75 in.

Laser

Waterjet

Sample parts from stainless steel and aluminum alloys, in three thicknesses, demonstrate the edge-quality differences when cutting with laser and waterjet.

16 METALFORMING / DECEMBER 2009 ONLINE www.metalformingmagazine.com