Page 22 - MetalForming November 2009

P. 22

New Press

Push Press Uptime Higher, PPMs Lower

Controls

An investment in state-of-the-art press- automation controls delivers a boost in uptime and a significant drop in internal PPM, and frees up the toolroom to focus on sensor installations rather than emergency die repairs.

BY BRAD F. KUVIN, EDITOR

Henry Ford once said that if you need a machine and don’t buy it, then you ultimately will find that you have paid for it, but don’t have it. In the metalforming and fabricating arena, Ford’s perspective easily applies to press controls, where significant technology advances have continued in spite of the economic climate. State-of-the-art controls offer increased ability to han- dle greater numbers of sensor inputs, and boast a host of new gee-whiz fea- tures. Now it’s up to metalformers to learn how to make use of such features to collect and convey press-

line data over wireless net- works, and to direct and optimize the functions of all of the equipment in a press line, including servo feeds and automated end-of-line packaging systems.

Those that attempt to handle complex projects with large, sophisticated and complex dies while using the control technology of yes- teryear soon come to real- ize how astute Henry Ford’s comment was. Bottom line: Metalformers need to upgrade to newer press con- trols, or run the risk of “pay-

20 METALFORMING / NOVEMBER/DECEMBER 2009

www.metalformingmagazine.com

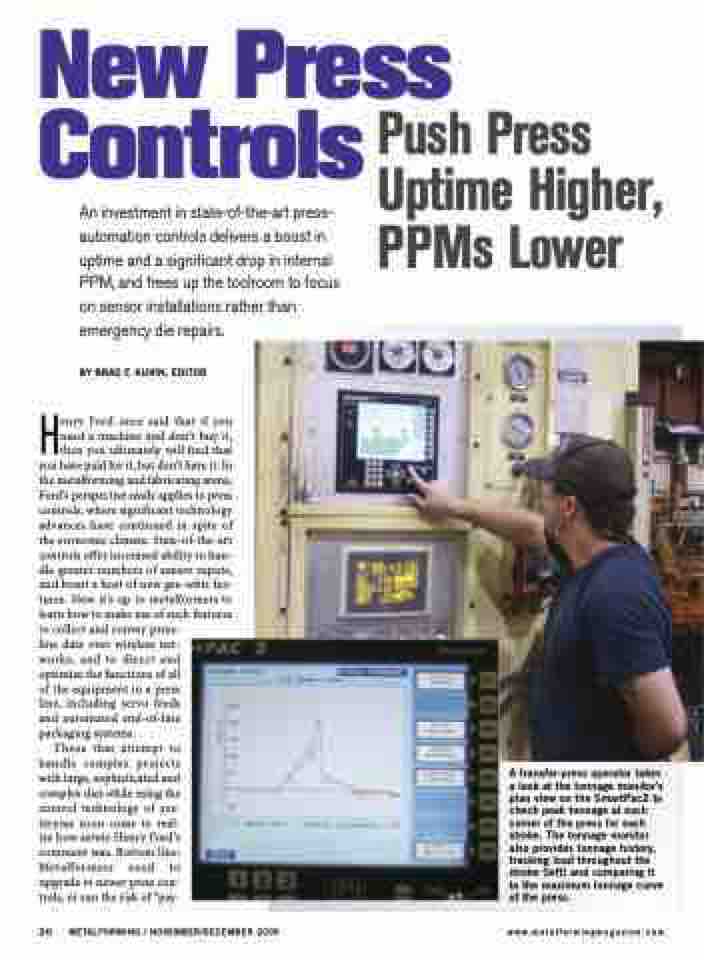

A transfer-press operator takes a look at the tonnage monitor’s plan view on the SmartPac2 to check peak tonnage at each corner of the press for each stroke. The tonnage monitor also provides tonnage history, tracking load throughout the stroke (left) and comparing it to the maximum tonnage curve of the press.