Page 59 - MetalForming October 2009

P. 59

Amino Mechanical Link Servo Drive Presses

Award Winning 2500 Ton press

METALFORM 2009 Booth #15035

Come see us and get control

Increase job flexibility and material formability

Reduce power consumption, machinery maintenance and tooling costs.

Optimize with in-die tapping fabrication and assembly.

shamilton@aminonac.ca

www.aminonac.ca

60

40

20

0

Location

n-value

0.20 0.25 0.35

0.45

0.20 = AKDQ 0.35 = 304 SS 0.25 = VD-IF 0.45 = 301 SS

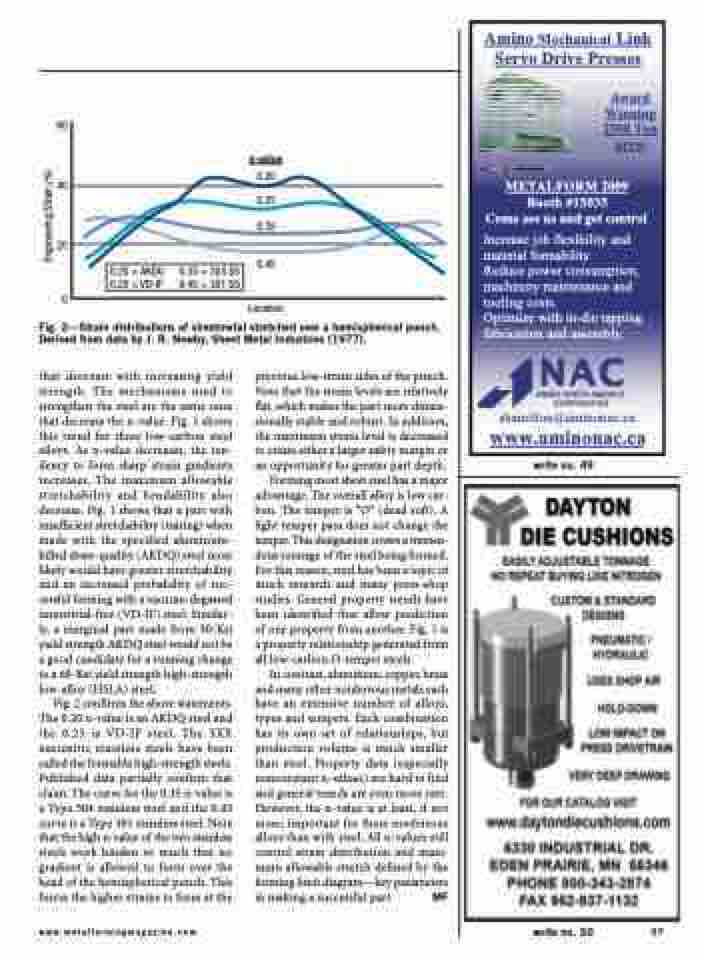

Fig. 2—Strain distributions of sheetmetal stretched over a hemispherical punch. Derived from data by J. R. Newby, Sheet Metal Industries (1977).

that decrease with increasing yield strength. The mechanisms used to strengthen the steel are the same ones that decrease the n-value. Fig. 1 shows this trend for three low-carbon steel alloys. As n-value decreases, the ten- dency to form sharp strain gradients increases. The maximum allowable stretchability and bendability also decrease. Fig. 1 shows that a part with insufficient stretchability (tearing) when made with the specified aluminum- killed draw-quality (AKDQ) steel most likely would have greater stretchability and an increased probability of suc- cessful forming with a vacuum-degassed interstitial-free (VD-IF) steel. Similar- ly, a marginal part made from 30-Ksi yield strength AKDQ steel would not be a good candidate for a running change to a 60-Ksi yield strength high-strength low-alloy (HSLA) steel.

Fig. 2 confirms the above statements. The 0.20 n-value is an AKDQ steel and the 0.25 is VD-IF steel. The 3XX austenitic stainless steels have been called the formable high-strength steels. Published data partially confirm that claim. The curve for the 0.35 n-value is a Type 304 stainless steel and the 0.45 curve is a Type 301 stainless steel. Note that the high n-value of the two stainless steels work harden so much that no gradient is allowed to form over the head of the hemispherical punch. This forces the higher strains to form at the

previous low-strain sides of the punch. Note that the strain levels are relatively flat, which makes the part more dimen- sionally stable and robust. In addition, the maximum strain level is decreased to create either a larger safety margin or an opportunity for greater part depth.

Forming most sheet steel has a major advantage. The overall alloy is low car- bon. The temper is “O” (dead soft). A light temper pass does not change the temper. This designation covers a tremen- dous tonnage of the steel being formed. For this reason, steel has been a topic of much research and many press-shop studies. General property trends have been identified that allow prediction of one property from another. Fig. 1 is a property relationship generated from all low-carbon O-temper steels.

In contrast, aluminum, copper, brass and many other nonferrous metals each have an extensive number of alloys, types and tempers. Each combination has its own set of relationships, but production volume is much smaller than steel. Property data (especially nonconstant n-values) are hard to find and general trends are even more rare. However, the n-value is at least, if not more, important for these nonferrous alloys than with steel. All n-values still control strain distribution and maxi- mum allowable stretch defined by the forming limit diagram—key parameters in making a successful part. MF

write no. 49

www.metalformingmagazine.com

write no. 50 57

Engineering Strain (%)