Page 30 - MetalForming October 2009

P. 30

Educational Conference

produced on an eccentric and a servo- drive press shows significant increases in production rates with servo.

• Productivity gains from servo technology for a variety of parts and press tonnages,100-1000 tons;

• Impact and considerations for dies and peripheral equipment; and

• Reducing energy consumption

with a servo-driven press.

Methods to Improve the Performance

of Metalworking Machinery—Keith Leatherwood, Vibro/Dynamics Corp.

Explains basic machine structural dynamics and vibration theory using technical illustrations and case studies, and describes the characteristics of a variety of isolators and mounting sys- tems, including elastomeric, coil spring systems, material and viscous damp- ing, leveling and nonleveling designs.

• Best machine-installation practices;

• Current installation technologies; and

• Machine structural dynamics and vibration theory.

Session S62

Lean Manufacturing Principles for the Pressroom II

Integrated Manufacturing and Business Processes Lead to Less Cost, Less Waste and Improved Efficiency —Mark Symonds, Plex Systems

Learn from two manufacturing IT leaders how integrated systems have helped their metalforming companies improve product quality and traceabil- ity, reduce waste, and save time as move to integrated systems.

• How and why to integrate IT and manufacturing and business processes;

• Case studies;

• The value of having information

updated automatically and made

accessible to all employees; and

• How integrated sys-

tems/information improves trace- ability and quality.

Wednesday, November 18

8 – 10 a.m.

Session S80

Cleaning and Lubricants for Stamped Parts I

Cost Benefits of High Performance Lubricants—Steve Lowery, Tower Oil & Technology Co.

Through the use of real-world issues facing stampers, case studies and several cost justification techniques will be reviewed, including a detailed cost analysis.

• Selecting high-performance lubricants;

• Tooling wear versus press uptime;

• Cost-evaluation techniques; and

• Case studies.

Cleaning Stamped Parts—Lloyd Hundley, Tower Oil & Technology Co.

This session will leave the participant with the understanding of cleaning methods relating to stamped parts.

• Realize cost savings by evaluating

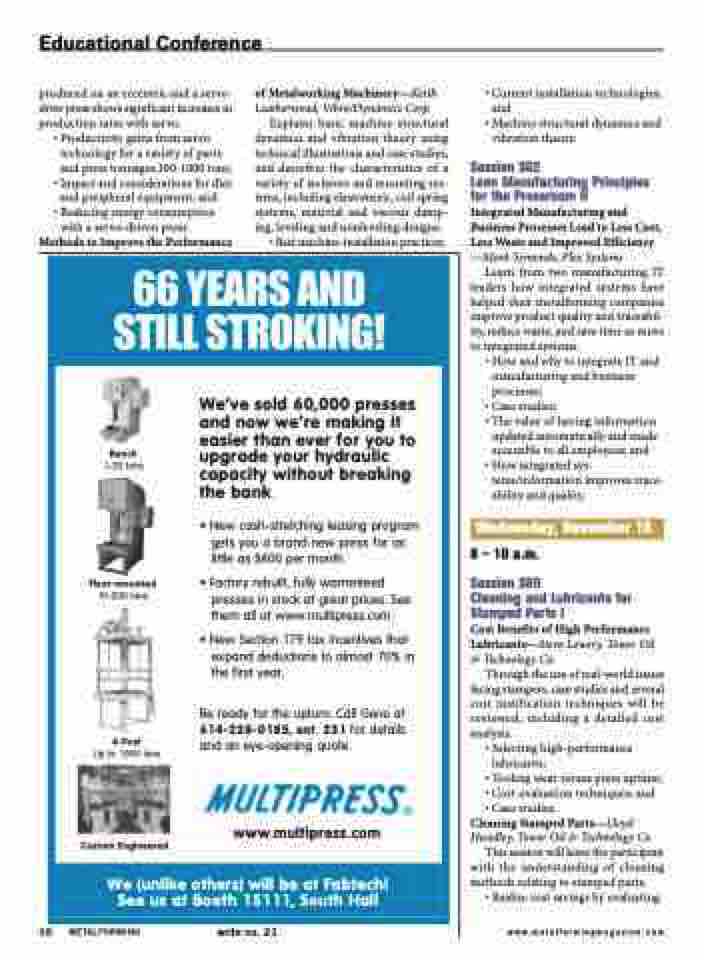

Bench

1-20 tons

Floor-mounted

10-200 tons

4-Post

Up to 1000 tons

Custom Engineered

We’ve sold 60,000 presses and now we’re making it easier than ever for you to upgrade your hydraulic capacity without breaking the bank.

• New cash-stretching leasing program gets you a brand new press for as little as $400 per month.

• Factory rebuilt, fully warranteed presses in stock at great prices. See them all at www.multipress.com.

• New Section 179 tax incentives that expand deductions to almost 70% in the first year.

Be ready for the upturn. Call Gene at 614-228-0185, ext. 231 for details and an eye-opening quote.

www.multipress.com

We (unlike others) will be at Fabtech! See us at Booth 15111, South Hall

28 METALFORMING

write no. 21

www.metalformingmagazine.com