Page 32 - MetalForming September 2009

P. 32

Tooling Technology

Stuart Keeler (Keeler Technologies LLC) is best known worldwide for his discovery of forming limit diagrams, development of circle grid analysis and implementation of other press shop analysis tools. Stuart’s sheetmetal forming experience includes 24 years at National Steel Corporation and

12 years at The Budd Company Technical Center, enabling him to bring a very diverse background to this column and the many seminars he teaches for PMA. His most recent project is technical editor of the AHSS Application Guidelines—Version 4, which now is available for downloading free from www.worldautosteel.org. Keeler Technologies LLC

P.O. Box 283

Grosse Ile, MI 48138

Fax: 734/671-2271

E-mail: keeltech@comcast.net

An attendee loudly made an impor- tant comment during a recent PMA seminar on sheetmetal forming. “When my steel work hardens during forming, it stalls the press. Where can I purchase steel without work harden- ing?” The ensuing discussion explained how stretchability and bendability are possible only when materials work harden. The real solution would depend on the actual cause of the press stalling—insufficient tonnage or lack of energy replacement. Inserting steel without work hardening would only create a major disaster.

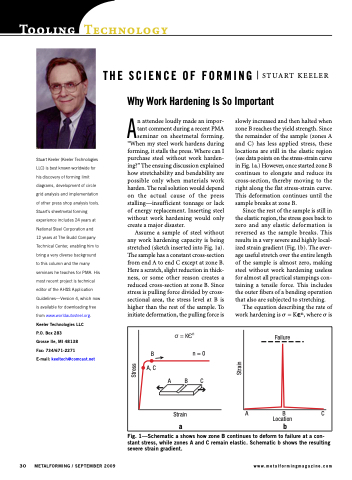

Assume a sample of steel without any work hardening capacity is being stretched (sketch inserted into Fig. 1a). The sample has a constant cross-section from end A to end C except at zone B. Here a scratch, slight reduction in thick- ness, or some other reason creates a reduced cross-section at zone B. Since stress is pulling force divided by cross- sectional area, the stress level at B is higher than the rest of the sample. To initiate deformation, the pulling force is

STUART KEELER

slowly increased and then halted when zone B reaches the yield strength. Since the remainder of the sample (zones A and C) has less applied stress, these locations are still in the elastic region (see data points on the stress-strain curve in Fig. 1a.) However, once started zone B continues to elongate and reduce its cross-section, thereby moving to the right along the flat stress-strain curve. This deformation continues until the sample breaks at zone B.

Since the rest of the sample is still in the elastic region, the stress goes back to zero and any elastic deformation is reversed as the sample breaks. This results in a very severe and highly local- ized strain gradient (Fig. 1b). The aver- age useful stretch over the entire length of the sample is almost zero, making steel without work hardening useless for almost all practical stampings con- taining a tensile force. This includes the outer fibers of a bending operation that also are subjected to stretching.

The equation describing the rate of work hardening is = Kn, where is

THE SCIENCE OF FORMING

Why Work Hardening Is So Important

B n=0 A,C

ABC

Strain

Failure

ABC Location

ab

30 METALFORMING / SEPTEMBER 2009

www.metalformingmagazine.com

Fig. 1—Schematic a shows how zone B continues to deform to failure at a con- stant stress, while zones A and C remain elastic. Schematic b shows the resulting severe strain gradient.

Stress

Strain