Page 14 - MetalForming December 2016

P. 14

2016Awards

of Excellence

in Metalforming

Excellence in Design— Federal Tool & Engineering

Federal Tool & Engineering, LLC, West Bend, WI, received the 2016 Higgins-Caditz Design Award. The company pro- vides metal components and manual assemblies to OEMs in the food-service-equipment, power-generation, on- and off -highway transportation, commercial-lighting and con- sumer-appliance markets.

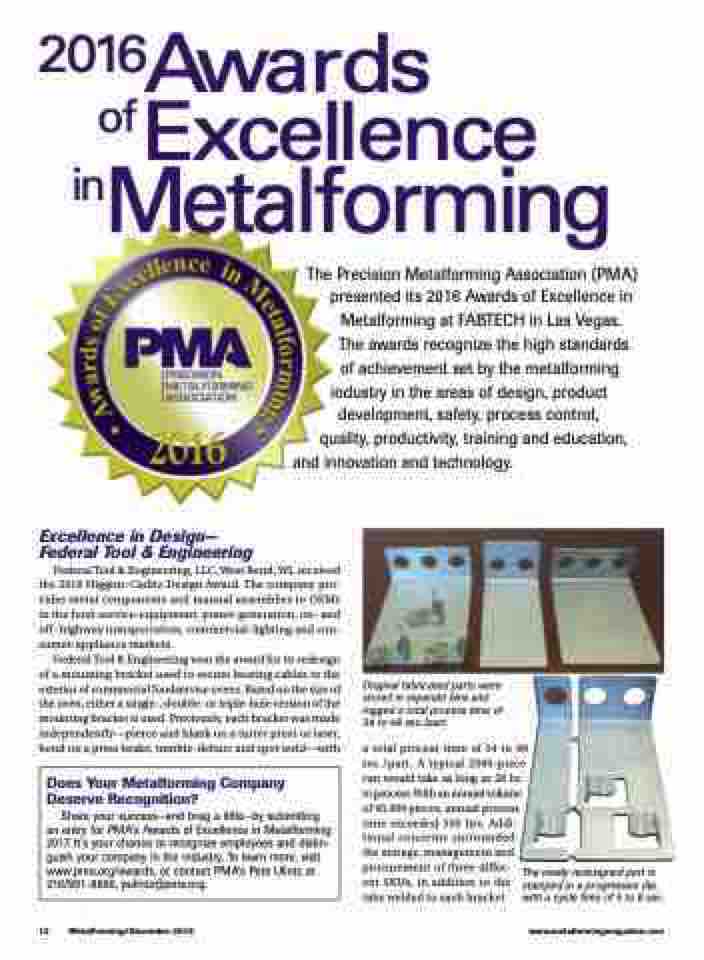

Federal Tool & Engineering won the award for its redesign of a mounting bracket used to secure heating cables to the exterior of commercial foodservice ovens. Based on the size of the oven, either a single-, double- or triple-hole version of the mounting bracket is used. Previously, each bracket was made independently—pierce and blank on a turret press or laser, bend on a press brake, tumble-deburr and spot weld—with

Original fabricated parts were stored in separate bins and logged a total process time of 34 to 48 sec./part.

The Precision Metalforming Association (PMA) presented its 2016 Awards of Excellence in

Metalforming at FABTECH in Las Vegas. The awards recognize the high standards

of achievement set by the metalforming industry in the areas of design, product

development, safety, process control, quality, productivity, training and education,

and innovation and technology.

12 MetalForming/December 2016

www.metalformingmagazine.com

a total process time of 34 to 48 sec./part. A typical 2000-piece run would take as long as 26 hr. to process. With an annual volume of 45,000 pieces, annual process time exceeded 550 hrs. Addi- tional concerns surrounded the storage, management and procurement of three differ- ent SKUs, in addition to the tabs welded to each bracket.

Does Your Metalforming Company Deserve Recognition?

Share your success—and brag a little—by submitting an entry for PMA’s Awards of Excellence in Metalforming 2017. It’s your chance to recognize employees and distin- guish your company in the industry. To learn more, visit www.pma.org/awards, or contact PMA’s Pete Ulintz at 216/901-8800, pulintz@pma.org.

The newly redesigned part is stamped in a progressive die, with a cycle time of 5 to 6 sec.