New Large-Bending Technology Ordered for Aircraft-Panel Production

April 1, 2018Comments

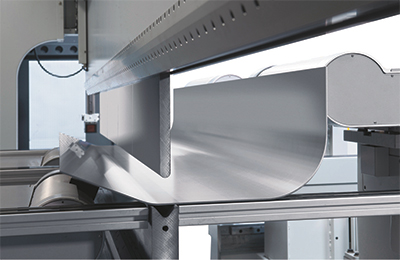

Kawasaki Heavy Industries (KHI) has ordered a custom-built 1000-ton Synchro-Form press brake from LVD Co., with the press brake equipped with special tooling to produce large panels for commercial-aircraft fuselages. Forming such large parts to a desired contour is challenging, which KHI believes will be simplified significantly via Synchro-Form. The press brake reportedly maintains angular consistency and required geometric profiles, and enables in-process automatic quality control when handling and positioning large parts, and performing multiple bends.

Kawasaki Heavy Industries (KHI) has ordered a custom-built 1000-ton Synchro-Form press brake from LVD Co., with the press brake equipped with special tooling to produce large panels for commercial-aircraft fuselages. Forming such large parts to a desired contour is challenging, which KHI believes will be simplified significantly via Synchro-Form. The press brake reportedly maintains angular consistency and required geometric profiles, and enables in-process automatic quality control when handling and positioning large parts, and performing multiple bends.

KHI in Japan is a key partner in production of the Boeing 777X, the successor to Boeing’s 777 aircraft. The 777X is slated to become the largest and most efficient twin-engine jet in the world, according to Boeing officials.

The Synchro-Form press brake meets tight tolerance requirements demanded on this application as well as the need for complete automation, according to LVD Co. officials.

LVD Co.: www.lvdgroup.com

See also: LVD North America

Technologies: Bending, Fabrication

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Fabrication

FabricationNew Abrasives Line Includes Flap Discs, Quick-Change Discs

Tuesday, May 7, 2019

Fabrication

FabricationNew Rapid-Delivery Program for Lifting and Positioning Equip...

Tuesday, May 7, 2019

Fabrication

FabricationRobot Tools for Drilling, Finishing and More

Tuesday, May 7, 2019