Extrusion

Function: Produces screw holes, tube holders and locators, and doubles as a connector.

Benefit: When paired with a round hole, the extrusion snaps and locks two parts in place.

Scratch

Function: Designed for sheet stopping and as a weld locator.

Benefit: Scrapes material into a stop on one side of the material, leaving no holes or marks on the opposite side.

Bridge

Function: Used for parts that require dividers, ventilation or wire tie-downs.

Benefit: Doubles as an efficient sheet-topping solution.

Cluster

Function: With two to 120-plus tips per punch, makes holes with each stroke of the machine.

|

| With two to 120-plus tips per punch, perforating with cluster tools is fast and efficient. |

Benefits: Less time required for punching and managing sheet stretch. Combats sheet distortion and oil canning that can result from perforation applications. Add a back-bending die to reduce distortion further.

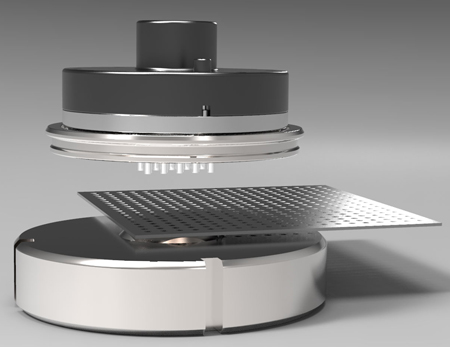

Louver

Function: Creates louvers for airflow or ventilation applications.

Benefit: Also can be used to create stops in less time and for less money than using jigs or fixtures.

Half Shear

Function: Aids in assembly and reduces the need for jigs and fixtures.

Benefit: An additional stopping option.

Multi-Scribe

Function: Offers an unlimited range of sheet-marking options.

Benefits: Used for both sheet scribing and dot-matrix marking on a range of materials, eliminating the need to change tools each time produce a different mark. MF

View Glossary of Metalforming Terms

See also: Wilson Tool International

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. CNC Punching

CNC PunchingWilson Tool Appoints Semerad Chief Commercial Officer

Friday, April 19, 2024

CNC Punching

CNC PunchingWilson Tool Announces New COO and Corporate Structure Change...

Thursday, August 17, 2023

CNC Punching

CNC PunchingPunch-Shear Combo Pushes Productivity Sky High

Thursday, July 27, 2023