Lou Kren

Lou Kren

Senior Editor

Fiber-Laser Cutting to the Rescue

January 1, 2017 Adoption of leading-edge technology can be an intimidating process. Lack of familiarity, trepidation surrounding what may be a steep learning curve and the ability to leverage such an investment into success, to say nothing of the level of investment itself, causes many manufacturers to stick with what’s tried and true. Tried-and-true, though a comforting proposition, often steers companies into the slow lane, as more agile competitors adopt and adapt, and speed on past along the manufacturing highway.

|

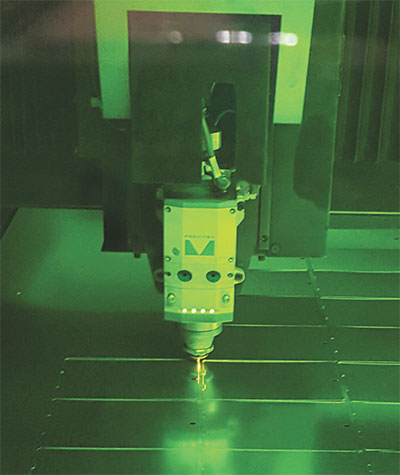

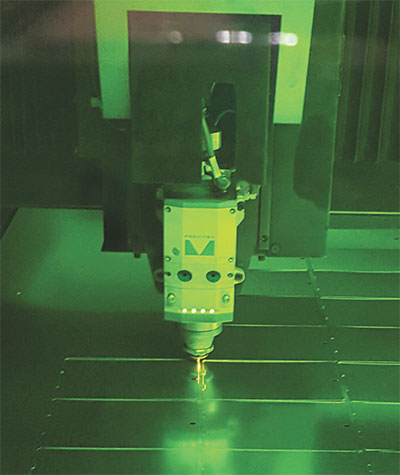

| A 3-kW fiber-laser cutting machine has allowed Weber Specialties to serve low-volume customers while gaining flexibility to produce prototypes and adapt quickly to changes in part designs, all while cutting lead time in part production. |

Weber Specialties Co., brought to life as a tool-and-die partnership in 1943, incorporated in 1955 and eventually evolving into a supplier of stamped and fabricated components, found itself in the position of having to adopt and adapt. And that it has done with the early-2016 addition of a fiber-laser cutting machine. The technology has filled a production hole at the Schoolcraft, MI, based manufacturer while also delivering flexibility as well as time and cost savings to its customers.

With two plants offering 100,000 sq. ft. of manufacturing space under roof, Weber Specialties and its 80 employees serve a variety of markets, including appliance, automotive, furniture, medical, electrical and industrial-hardware. It performs tool build, stamping, fabricating, assembly and painting inhouse, using a variety of part materials. Though successful, the company wanted to limit some of its outsourcing operations.

“We were outsourcing CO- and fiber-laser work,” recalls Andy Bozell, vice president of engineering at Weber Specialties. “We wanted to address extended lead times due to outsourcing, challenges related to breaking in to the production schedules of outside suppliers, and quality control of the parts.”

|

| The new laser-cutting machine easily handles Weber Specialties’ typical part stock, including low-carbon, coated and stainless steel; advanced high-strength steel; aluminum; brass; and nickel; in thicknesses from 0.010 to 0.5 in. |

In addition, though proficient at high- and medium-volume work, “the need for a new machine centered around trying to address increasing demand in the low-volume work environment, using laser capability to cut ferrous materials,” he adds.

Originally, the company considered the possibility of adding a CO2 machine. “We tried to justify a laser in the past and finally got to that level,” Bozell explains. “We decided that we wanted to adopt the new technology and explore fiber-laser cutting machines. They are fast, and we could gain so many efficiencies with them.”

Ideal for the Material and Volume Mix

After a four-month search, in February 2016 Weber Specialties brought a new fiber-laser cutting machine to the shop floor, a FS 3015 model from HK Laser & Systems USA, Lombard, IL. (Weber Specialties ultimately added a CO2 machine, dedicated to cutting Mylar for a specific project.)

An upgrade to 3-kW power enables the FS 3015 to easily handle the company’s typical part stock, including low-carbon, coated and stainless steel, advanced high-strength steel, aluminum, brass, and nickel, in thicknesses from 0.010 to 0.5 in.

The machine features a durable rack-and-pinion motion system, lightweight cutting bridge with synchronized dual servo motors and a quick-change noncontact cutting head. Offering energy saves to 70 percent as compared with traditional CO2 laser cutters, the FS 3015 provides cutting feed rates to 1000 in./min and traverse speed of 6700 in./min. with 1.5-G acceleration, according to HK officials.

Upon install, the company, benefitting from offsite and inhouse training backed by the machine’s library of material-cutting conditions and job-recall capability, quickly realized the advantages of fiber-laser cutting.

“It really increased our ability to help customers develop parts in a quicker manner,” Bozell says. “We can make multiple iterations of a fabricated part very quickly to validate a concept with our customers, so it helps us in the early suppler-involvement process of part

|

| Weber Specialties added storage racks to handle sheet for the hungry laser cutter, and is looking at ways to add sheet remnants to its inventory-management system to better serve low-volume customers that may not require full sheets for limited part production. |

development.”

For low-volume work, the machine is ideal as it negates the need to create hard tooling, a costly venture for producing parts of limited quantities. In fact, “the new laser-cutting machine completed our solution to multiple-volume demands,” says Bozell. “We were a stamper for a long time, where the high-volume work was easy for us, and we did some work with quick-die-change on the tooling to better handle intermediate runs. Now we can handle from one to 1 million parts for our customers.”

On the shop floor, Weber Specialties employs the fiber-laser cutter as a standalone machine.

“We run various amounts of different materials and different products through it,” says Bozell. “We use it to feed our forming and fabricating departments, and spot-welding department, so it’s a launching pad for a lot of our low-volume products produced in those areas.”

Bozell points to a number of examples where the machine has paid off.

“For quite some time we had been fabricating a stainless-steel panel for a customer, who then introduced a size variation in that product,” Bozell recalls. “We used a hard tool to create one size of that part, but because we added a laser cutter we were able to create a whole family of those different-sized products just by changing blank development to a laser-cutting process instead of a die-cutting process. Without the inhouse laser cutter, we would have had to outsource that work.”

Such flexibility enables rapid reaction to customer changes, and also assists with customer indecision.