Stuart Keeler

Stuart KeelerCoping with the New Steel Properties and Processes

January 1, 2017Comments

For several decades beginning in the 1960s, identification of steel properties was quite simple:

- Yield strength: Point at which elastic stress changed to plastic stress

- Tensile strength: Maximum height of the stress-strain curve (onset of width-neck)

- Total elongation: Amount of elongation in 2 in. as necking begins to tear.

Then more complex grades arrived for production use: vacuum-degassed interstitial-free; many strength levels of high-strength low-alloy; and other types. These steels required additional properties to describe capability:

- Workhardening exponent or n-value: Capacity to restrict local strain gradients

- Strain-rate hardening or m-value: Response of material to increased deformation rates

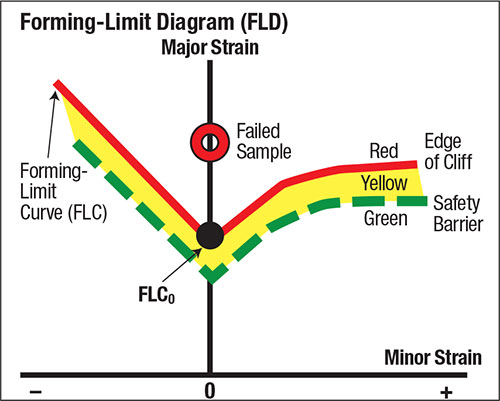

- Forming-limit curve: Defining how close deformation is to failure (see diagram).

By the early-1990s, computerized forming simulation or virtual forming emerged with great success. Tremendous time and money were saved by conducting part design, die design, product capability and other tasks on the conputer. However, the output was only as good as the quality of the steel properties and the FLC data.

|

| FLC for deterring the severity of deformation at different locations in a stamping. |

“Why should there be only one phase in the microstructure?” asked metallurgical researchers. Research led to creation of the first two-phase steel, called dual-phase (DP). Ten-percent martensite (MS) balls were introduced into the ferrite base. As deformation begins, the ferrite and martensite interact with each other to create higher n-values. This good news allowed DP steel to restrain the early growth of local strain gradients. Unfortunately, the n-value is not constant and must be plotted as an instantaneous n-value graph.

Here Come the Designer Steels

Further research led to transformation-induced-plasticity (TRIP) steel that allowed creation of higher n-values over the complete deformation time of the sheetmetal. ‘Designer steel’ frequently was the name attached to this material. The high n-values are held in reserve. Strain transforms the retained austenite to MS. If the steel has low carbon-retained austenite, the transformation will take place when the metal is formed into the part. If high carbon-retained austenite is available, no transformation takes place when forming the part but is used to absorb energy during a car crash or other high-energy event.

The current operating system includes the use of nano-sized particles. Using the large MS balls for DP and TRIP steels too often causes an unwanted reaction in the steel. Edge cuts, notches, holes and other locations of shearing induce coldworking, thereby reducing formability and initiating cracking, broken edges, change in part shape and other forming barriers.

The nano programs replace each large MS ball (such as found in DP products) with huge numbers of nano-sized MS particles. These particles protect their surrounding areas and link with neighbor particles. Some major universities are now undertaking ‘nano projects’ as the next major advancement in metallurgical science.My concern: Most applied research for sheetmetal forming is found in the press shops—developing part designs, die designs, running presses, using welding equipment and many other assignments. The old days of identifying material characteristics and properties by yield strength, tensile strength and total elongation are long gone.

Therefore, in-depth training programs, seminars, classes and other means of learning now are required. More accurate information about a given coil will be needed because the final buyers of the parts must meet more exacting requirements. However, this training must be presented in a manner understood by the students. MF

View Glossary of Metalforming Terms

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsSurvey: North American Metals-Industry Outlook

Wednesday, March 20, 2024

Hot-Stamped Steel and Aluminum Drive Autobody Changes

Daniel Schaeffler, Eren Billur Thursday, February 8, 2024

Materials

Materialsthyssenkrupp Materials de México inaugurates New Service Cen...

Wednesday, January 31, 2024

Materials

MaterialsAlro Steel Acquires Pottinger Steel

Monday, November 6, 2023