Techniques to gain customer perspectives and insights can include formal customer-feedback forms delivered with the first shipment of a new part, or an in-person meeting conducted by a member of the leadership team, such as a CEO or company president. These meetings should include requests for direct feedback from customers, such as, “What’s working or not working? What services would you like to see us offer? What pressures do you experience at your company?”

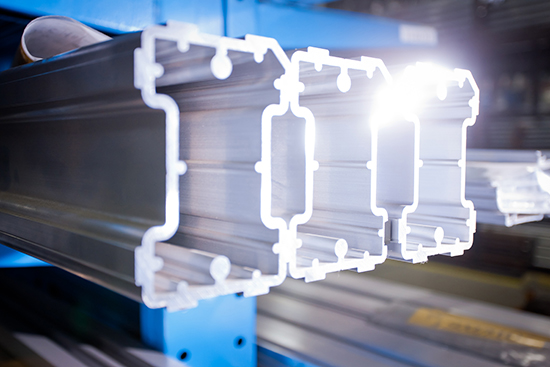

Insights from customers can prompt expansions beyond just metal stamping or fabricating, for example, and into related fabrication techniques such as stretch-forming and bending. These insights also prompt expansion into complementary services such as precision machining, finishing, welding and complex assembly.

OEMs no longer need to conform to the conventional idea of using multiple suppliers. A single-source supplier that can extrude, machine, bend, stretch-form, finish, weld and assemble brings additional value to such a customer’s fabrication needs.

3) Understand your vision and have a plan

There’s a difference between a company on a journey and one that is drifting. Journeys require a direction and—when done with others—a plan. Becoming a vertically integrated, single-source fabricator does not mean responding with a “Yes” to every customer request and opportunity. Hard decisions must be made, and a vision and plan are crucial to guiding those decisions.

While developing a business plan annually is a standard operating procedure, a strategic, long-term vision with measurable objectives enables managers to see beyond what’s in front of them today. A vision plan should detail the journey your company will take to become the company you envision in five years. Sharing this vision with customers shows them that in addition to meeting their manufacturing needs today, you can anticipate and plan for their future needs.

This vision includes doing more for customers, and requires fabricators to commit to growth through capital investments and acquisitions. By listening to what your customers want, consider opportunities to grow into new markets. Faced with opportunities every day, fabricators need discipline to identify the right opportunities to pursue instead of haphazardly and counter-productively leaping at each one. A central vision and plan serves as the foundation for that discipline.

4) Share expertise with customers

While fabricators are experts in the most effective and efficient ways to manufacture customers’ designs, vertically integrated suppliers offer application expertise in addition to high-quality products. This type of supplier offers expert engineering resources that improve overall manufacturability. Such a supplier provides education on selecting the right raw material given the product’s end use, or shows customers ways to account for secondary processes such as material finishing and coating. Oftentimes, vertically integrated suppliers help in implementing geometrical dimensioning and tolerancing —all of which can help fix potential problems in the design phase. From the perspective of customers, when fabricators share this kind of design-assist expertise, it elevates them from component supplier to business partner.

5) Market to customers how you manage risk

While OEMs aggressively seek supplier consolidations, they remain wary of which fabricators will actually deliver. Fabricators must minimize the perceived risk customers feel when moving their business from one supplier to another with elevated capabilities. To lower risk and make your company more attractive to potential customers:

• Acquire third-party certifications, such as ISO and market-specific certifications, to demonstrate quality design and manufacturing processes.

• Use statistical measurement and process control to support data-driven predictions.

• Focus on quick-response manufacturing, inventory management and cost-reduction initiatives to improve product manufacturing and quick-turn production capabilities.

Then, market why a customer moving its business to yours makes sense. A single-source supplier offers these and other advantages to the customer:

• Higher-level understanding of the importance of form, fit and function with mating components;

• Communicating one expectation or future direction to a single supplier versus multiple channels;

• The elimination of transit damage caused by multiple suppliers handling products; and

• Duplicate production services to mitigate risk for disaster recovery.

Doing and being more for customers requires commitment from fabricators to critically assess how they’re responding to customer needs and react accordingly. These five strategies can help, thus making your company more attractive as a single-source supplier. MF

View Glossary of Metalforming Terms

Technologies: Management

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementDOL Announces Nearly $200 Million Allotted for Registered Ap...

Friday, March 1, 2024

Management

ManagementLaurie Harbour, President, Harbour Results, Inc., E707

Wednesday, January 24, 2024

Podcast

Podcast

Video

Video