Dual Heads, Plus Beveling

Further enhancing service-center throughput: all 11 of Jacquet’s waterjet-cutting machines are dual -head models, and are run off of 100-hp intensifier pumps. Standoff between the heads is adjustable either automatically (through the cutting program) or manually.

Adding the second cutting head increases machine purchase price by just 20 percent or so, making the decision to effectively double output easy to justify, says Engle. “The twin-head design is a must as we strive to increase our speed to market and reduce turnaround time.

“Also, we experience no decrease in traversing or cutting speed with the second head,” Engle adds, “while holding our tight cutting tolerances.”

Jacquet offers customers a choice of three levels of cut quality, with finer cuts or those with tight edge-squareness tolerances and that run at slower speeds priced at the high end. Less-critically toleranced parts that can be cut at higher speeds are priced slightly less.

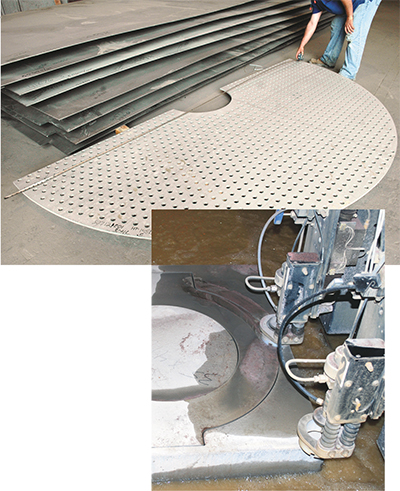

“The trend,” says Engle, “is toward the high end. And that includes the ability to provide beveled cut edges to facilitate welding of cut parts without the need to run the cut edges through a secondary process to add the bevel.”

Three of the firm’s 11 machines have been custom-engineered by Jet Edge to allow them to provide beveled cut edges—machines in Racine, Pottstown and Houston. Applications for this capability include cutting large plates that are then rolled and welded to manufacture tanks and vessels for the oil and gas industry, among other end-use applications. MF|

10 Tips for Maximizing Waterjet Uptime …provided by Jet Edge, Inc., St. Michael, MN; www.jetedge.com. Successful waterjet operations like those at Jacquet rely on the performance of proper routine maintenance on the machines. With waterjet operating pressures often exceeding 75,000 psi (5200 bar), proper maintenance will help ensure maximum uptime, productivity and profitability. It can mean the difference between winning and losing customers, and retaining existing customers. Neglecting a waterjet system can result in costly downtime, lost opportunities and expensive yet preventable repairs. At ultra-high pressure, small leaks left ignored can turn into big and costly problems. Hydraulic oil left unchanged can break down and gum up a pump’s directional control valve, causing the pump to stop working. Cooling systems that are allowed to clog with mineral deposits can cause a pump to shut down. And, improperly torqued high-pressure components can cause short seal life and premature component failure. Fortunately, all of these problems can easily be avoided by following your waterjet-manufacturer’s maintenance guidelines and taking the time to properly maintain your equipment. Here are 10 tips for preventing many of the common problems associated with improper waterjet-cutting machine maintenance. 1) Read, understand and follow the procedures in the manufacturer’s maintenance manual and take advantage of manufacturer training programs. Jet Edge offers its customers free training for the life of its machines every other month at its Minnesota headquarters. 2) Keep the pump cool. Hydraulic intensifier pumps use a heat exchanger to cool the pump’s hydraulic fluid; direct-drive pumps use water to cool the interface plate between the plunger pump and the high-pressure assembly. Cooling can be accomplished with a closed-loop chiller or with tap water—tap-water temperature should not exceed 70 F. If your water contains heavy mineral deposits, filter and soften it to minimize the deposits within the intensifier pump’s heat exchanger, and periodically clean the heat exchanger following the instructions in your maintenance manual. If excess scale develops within the heat exchanger, it will not efficiently cool the pump’s hydraulic fluid and the pump will shut down. 3) Use clean and cool water. Jet Edge recommends that cooling water and incoming process water be no warmer than 70 F and that it be pretreated to <100 TDS, PH 6-8, Silica <15 PPM. Replace pump water filters after every 250 hr. of operation, or possibly more frequently depending on local water conditions. 4) Hydraulic fluid must be clean. Follow the manufacturer’s guidelines for replacing hydraulic fluid and hydraulic and breather cap filters. When changing the fluid, take care to not contaminate the new fluid by keeping the working area around the system dry and free of dust, dirt and debris. 5) Closely follow the manufacturer’s pump startup and shutdown guidelines. Bring the pressure up slowly when powering on the system and bring the pressure down slowly when shutting down the system. 6) Properly maintain high-pressure components and seals. Replace leaking seals and tighten high-pressure leaks as soon as they occur. Even a small leak, if neglected, can cut a groove into an expensive high-pressure component, forcing you to spend time lapping the component or replacing it. Use two wrenches to tighten high-pressure fittings. When replacing intensifier seals, follow the manufacturer’s torqueing guidelines; improper torqueing often is the cause of premature pump-component failure and short seal life. Inspect and service high-pressure tube poppets when necessary, and follow maintenance guidelines for servicing the on/off valve and rod seal. 7) Keep the pump and motion system clean and well lubricated. 8) To maintain a consistent level of quality, have the motion system recalibrated periodically by an experienced technician. 9) Use quality orifices and monitor the orifice, nozzle and mixing chamber to ensure optimal cutting performance. An abrupt pressure loss often can be attributed to a damaged or blown-out orifice. 10) Use quality, clean and dry garnet and ensure that debris does not fall into the abrasive hopper when filling it. Supply dry air to the abrasive hopper. |

View Glossary of Metalforming Terms

See also: Jet Edge Waterjet Systems

Technologies: Cutting, Fabrication

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingNew Line of Wear-Resistant Waterjet Nozzles

Friday, February 24, 2023