Powerful Flat-Pattern Development Integrated in SolidWorks 2013

March 1, 2013Comments

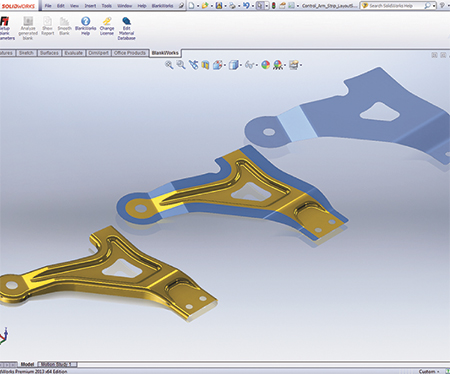

Forming Technologies Inc. (FTI), Burlington, Ontario, Canada, developer of software for the design, simulation and costing of sheetmetal components, announces the worldwide release of BlankWorks v5.0. BlankWorks provides SolidWorks 2013 users with a fully integrated add-in application for developing optimal flat patterns from complex 3D designs.

BlankWorks, commonly used for flattening complex 3D sheetmetal components, also can be employed for flattening a variety of other SolidWorks designs, including vinyl decals, canvas tents, swimming-pool liners, upholstery, boat hulls, aircraft and helicopter parts, insulation, thermoform packaging, electronics, and consumer product components.

“During the past 13 years, a variety of industries that design complex 3D parts manufactured from 2D raw material have adopted BlankWorks for flat-pattern development,” says Dan Marinac, FTI director of business development. “However, the most common industry served is progressive-die tooling design.

“BlankWorks 5.0 gives SolidWorks 2013 users a competitive advantage during the die-tryout stage of tooling development,” continues Marinac. “Trial-and-error methods traditionally used to develop complex flanges and flat-pattern shapes can take days to weeks to develop. Using BlankWorks, users can develop flanges and blank shapes for their stampings in less than one minute.”

Among the new features in Blank-Works 5.0 is feature-line mapping, which allows users to map lines and edges from part to flat pattern or curved surface. This becomes important for precisely locating manufacturing details such as surface edges, holes, bend lines or paint lines on the 2D blank prior to stamping. Further, FTI has added a sketch showing the minimum rectangular blank encompassing the flat pattern.

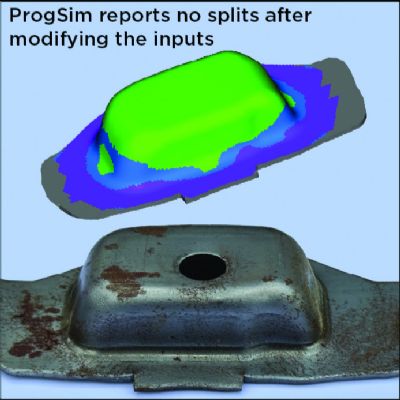

In addition to flat-pattern development and flange unfolding, BlankWorks also provides a contour plot indicating the thickening and thinning resulting from the forming process. It accounts for material stretch and deformation as well as bending, and can flatten any SolidWorks geometry including imported data. The software also can be used to assess the feasibility of a part for manufacturing.

Forming Technologies Inc.: 905/340-3370; www.forming.comView Glossary of Metalforming Terms

See also: Hexagon Manufacturing Intelligence

Technologies: Software