Gauging Future Growth of AHSS in Light Vehicles

July 1, 2011Comments

A report from market researchers at Ducker Worldwide, presented at the recent Great Designs in Steel seminar, predicts double-digit growth of advanced high-strength steels in light vehicles, through the next several years. The report, presented to the more than 1500 GDIS attendees (May 18, in Detroit, MI), studies AHSS content in unibody and full-frame vehicles, and offers a trend line through 2020 of AHSS content per vehicle.

Ducker’s market analysis, presented by senior analyst and program manager Abey Abraham, reveals that in 2010, 9.6 percent of the 14.5 million tons of flat-rolled steel consumed in North American light vehicles had tensile strength in excess of 550 MPa. The average unibody vehicle contains more than 150 lb. of AHSS in its body, closures and bumpers, or 15.4 percent of overall steel content. Meanwhile, full-frame vehicles average 139 lb. of AHSS, and 8.2 percent of overall steel use.

Since 2006, says Abraham, the amount of flat-rolled AHSS content in North American light vehicles has grown by 18 to 19 lb. annually, and he finds no reason to believe that this trend line won’t continue. Ducker forecasts that by 2020, the average vehicle will contain 346 lb. of AHSS. This compared to 81 lb. in 2006 and an expected 175 lb. for 2011. Further, should the pending 2017-2025 CAFE (CO2 and fuel economy) mandate become enacted, Ducker estimates that AHSS content could skyrocket to around 500 lb./vehicle by 2020, due to increased lightweighting strategies.

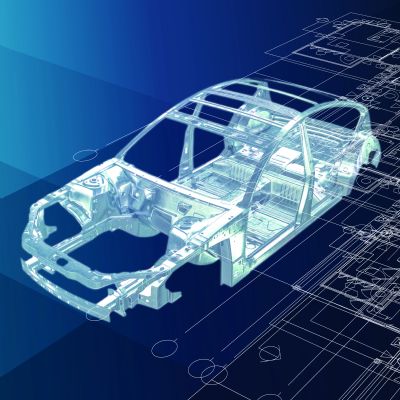

Where can we expect to see more AHSS in light vehicles? Abraham says that 50 percent of the average body-in-white will be converted to AHSS in this decade—door structures, front rails, roof reinforcements, waistline beams, side-rail reinforcement, pillars and other strength-critical parts.

Download all of the presentations from Great Designs in Steel 2011 at www.autosteel.org/resources.Technologies: Materials