Simulation Software Offers Enhanced Die-Face Engineering Capabilities

February 1, 2012Comments

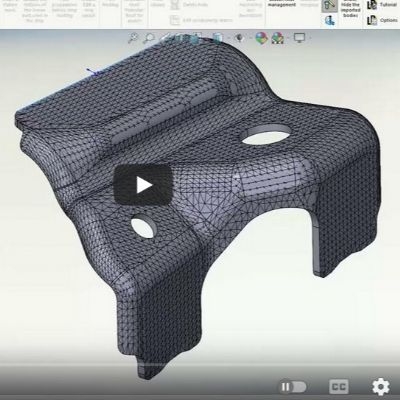

Engineering Technology Associates, Inc. (ETA), Troy, MI, announces the availability of Version 5.8.1 of its Dynaform die-system simulation software. Available for immediate download, the FEA software guides engineers through a variety of stages in the manufacturing process, from cost estimation and die-face design to formability analysis and stamping-process simulation. Notable enhancements are delivered through the Dynaform Die Face Engineering (DFE) module, which now offers the capacity to parametrically build die faces for a symmetrical part. Therefore, after the user defines the symmetry line, the program can automatically build the die faces for the other half of the symmetrical part accordingly. The DFE module also features a new Auto Mesh option that allows the user to automatically mesh the CAD model immediately after it has been imported.

Version 5.8.1 also includes a new product change replacement feature that allows the user to retain the current die-face design and drop in new product-design surfaces, saving time while improving flexibility. And, the new version allows the user to set up a personalized drawbead library that links the line bead force and the drawbead geometry shape. As a result, the user can elect to run the simulation with either the line beads or geometry beads.

Also enhanced with the new release is the Blank Size Engineering module, improved by of a streamlined guided user interface (GUI). New dialogues within the GUI contain tabbed menus for simplified navigation between functions.

Engineering Technology Associates: 248/729-3010; www.eta.comView Glossary of Metalforming Terms

See also: ETA (Engineering Technology Associates, Inc.)

Technologies: Software

Webinar

Webinar