Feature-Driven Process-Content Die-Planning and Costing System

January 1, 2011Comments

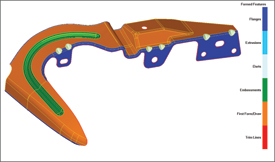

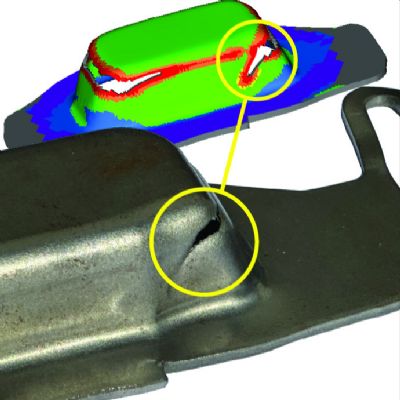

Forming Technologies Inc. (FTI), Burlington, Ontario, Canada, has introduced its FormingSuite Process Planner, a product-geometry feature-based and process-content-driven system to determine process layout and die cost. Process Planner helps users

|

Formingsuite’s Process Planner includes a customized spreadsheet that allows the user to establish the material cost, die cost, number of operations and the process cost early in the design/planning process. Process Planner also can be used in batch scenarios and is incorporated in the Automatic Costing System (ACS) for whole car or whole car program analysis.

Forming Technologies Inc.: 905/340-3370; www.forming.com

See also: Hexagon Manufacturing Intelligence

Technologies: Software

Webinar

Webinar