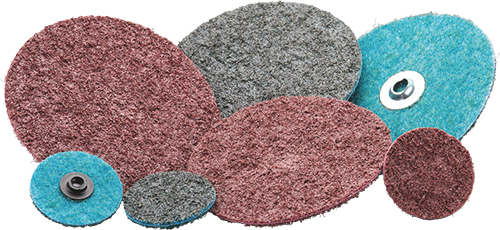

Long-Life Non-Woven Discs for Stock Removal and Blending

February 1, 2018Comments

Norton | Saint-Gobain Abrasives, Worcester, MA, has introduced Norton Rapid Prep XHD coarse and medium discs, designed to solve users’ most aggressive stock-removal and blending challenges during tool- and part-finishing operations. The extra-heavy-duty nonwoven discs remove weld lines, weld splatter, weld discoloration and blend surfaces in a single step.

Norton | Saint-Gobain Abrasives, Worcester, MA, has introduced Norton Rapid Prep XHD coarse and medium discs, designed to solve users’ most aggressive stock-removal and blending challenges during tool- and part-finishing operations. The extra-heavy-duty nonwoven discs remove weld lines, weld splatter, weld discoloration and blend surfaces in a single step.

XHD coarse discs are ideal for aggressive weld removal and surface blending on steels, while XHD medium discs work well on softer metals and alloys. Users will save labor and consumable costs by reducing application steps, as compared with the use of coated flap discs. These new Rapid Prep XHD discs offer a unique combination of a conformable fiber matrix and premium ceramic grain, resulting in improved cut control and surface blending over traditional coated flap and fiber discs. Product life is increased and shape integrity is maximized due to blended fiber webs that dissipate workpiece debris, according to company officials. In addition, the Norton Clean Bond resin system prevents smearing and produces a controlled wear rate.

“Test results have been exceptional. In comparison tests fabricators and welders will see a 26-percent higher cut rate, with less shedding, and two times the life over the top competitive product using the new Norton nonwoven discs,” says Mario Davila, Norton | Saint-Gobain abrasives product manager.

Rapid Prep XHD discs are offered in multiple sizes and nonwoven types, and both coarse and medium discs are stock items.

Norton | Saint-Gobain Abrasives: www.nortonabrasives.com

View Glossary of Metalforming Terms

Technologies: Finishing, Other Processes