Customizable with as Much Automation as You’d Like

Prior to investing in automated bending, Kennedy advises that manufacturers do their homework, and make decisions based on time studies and trial runs to ensure that systems produce needed parts quickly and to spec. They may find that bending centers indeed are better alternatives to just adding more of the same.

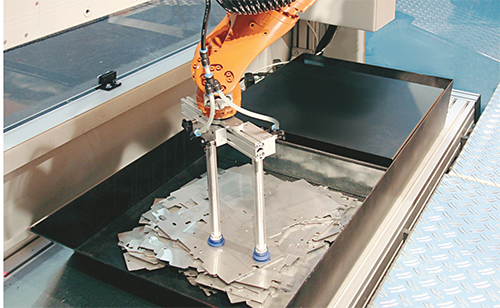

“Bending centers can be automated for users’ unique needs,” he says. “These can provide lights-out operation, from blank loading to part-off. Whether a run is two parts or 2000, a fully automated bending center can set up and run jobs by itself.”

Close examination of parts can help in decision-making.

“Folding and bending machines cannot achieve the tight bend radii of press brakes,” Kennedy says. “A contract manufacturer most likely is told what the radius must be. An OEM, on the other hand, can adjust the radius. Here, folding and bending machines prove successful if the radius is acceptable. In some cases, radii are changed to achieve productivity gains. And, you have all of the benefits of folding, which include quicker setup times, and greater accuracy because a press brake involves a V-die that requires more attention to get good, repeatable parts.”

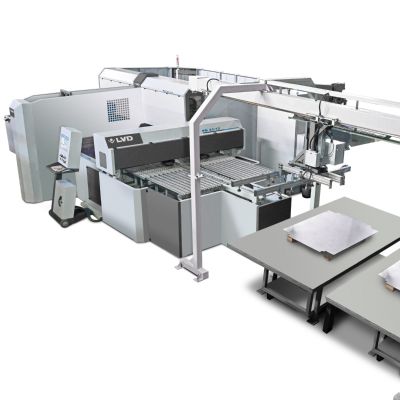

Software advances and modular design allow for automation to be added to core bending centers. Here, blanks automatically are picked and placed for folding.

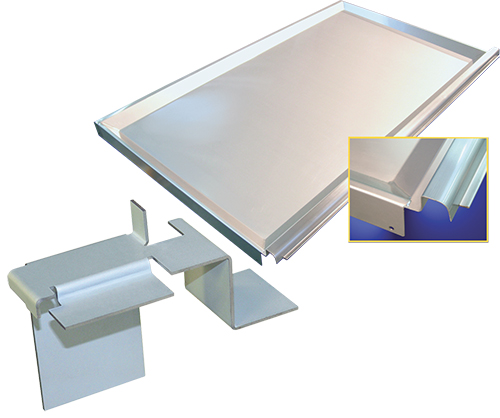

What parts are ideal for bending systems? Consider what Kennedy says are produced on his company’s equipment. The MiniBender, he explains, capable of churning out parts from 1 by 3 to 24 by 24 in., typically produces internal brackets, small chassis and other simple and complicated pieces.

The MultiBend, capable of producing parts from 9 by 10 in. to 60 by 120 in., often is employed for building refrigeration cabinets, outside power cabinets and other large parts. So it’s clear that current bending technology can handle a wide assortment of tasks.

“We’ll perform time studies on particular parts to help manufacturers compare a bending system with their current processes, so that they can get an idea of return on investment,” he explains.

Software Key to Success of Newer Systems

Software represents the greatest revolution in folding equipment, especially in regard to automated bending centers.

“Software is really driving bending technology these days,” Kennedy offers. “Ease of programming and ease of setup, all hallmarks of modern folding systems, result from software improvements.”

While mechanical technology has improved, many bending systems employ somewhat similar mechanical components and systems dating to the early 1990s, but software and electronics have evolved by leaps and bounds, enabling automated bending to compete and often surpass other processes in speed, accuracy and quality.

“Once a drawn part is fed to the system and some programming completed for tool selection, users experience a correct first part. Today’s bending centers, are fed by CAD systems and offer features such as automated tool changing to speed the process and decrease setup time while producing parts that are more accurate and repeatable than ever.”

Modular construction also assists in providing users with reliable customized systems. For example, notes Kennedy, many centers provide entry-level automation with additional modules available to handle part loading and unloading as well as other functions.

The software and related automation advances need not stress your maintenance department either, stresses Kennedy.

“Some fabricators with multiple bending centers have well-equipped maintenance staffs well-versed in this technology, but smaller manufacturers with, say, one machine, can take advantage of the machine builder’s service personnel,” he says, noting that RAS often supplies preventive-maintenance contracts to assist in ensuring that equipment stays fit and active. In addition, today’s software allows for remote access to diagnose and assess system operation, and quickly place systems back in service.

“When you make the investment, you want your system running, so a good equipment supplier will be proactive with support,” says Kennedy, who offers one more nugget on software and controls improvements in bending systems. “The young people coming into the industry are smarter than ever when it comes to working with software, controls and the latest interfaces, so that makes things easier all the way around. It is unfortunate in one respect that we have lost a lot of our trade, but we are competing in a world marketplace and you have to get with the program, so it helps that the younger generation is so comfortable and capable with newer technology.” MF

View Glossary of Metalforming Terms

See also: RAS Systems, LLC

Technologies: Bending