Mind Control Platforms, Integration During Quoting

As Eby points out, a single communication protocol with line components employing identical control processors is an ideal route for line integration. Beyond that, what should metalformers consider when contemplating additions to an existing press line?

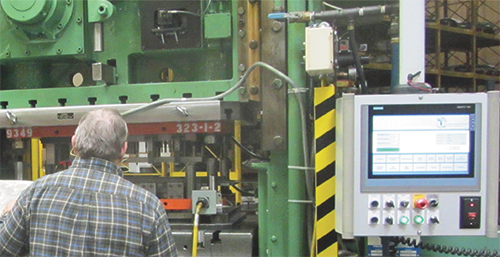

“When buying new equipment for a press line, do your best to buy equipment with matching control platforms (PLCs, HMIs, drives, etc.),” he explains. “Ask for specific manufacturers and model numbers of equipment in order to check the specifications to make sure that you’re receiving matching hardware platforms. And, hire a third party for technical assistance if you don’t have the needed technical expertise inhouse. Diligence on the front end in ensuring commonality across the line will help when it comes to keeping common spare parts, ensuring smooth line communications, and easing maintenance upon run-off and after the manufacturer/integrator has left your plant.”

Eby also recommends considering the age and condition of existing controls that must be tied together with new equipment.

“Just because a piece of equipment works does not mean that it will integrate cleanly,” he says. “Many times, stampers purchase nice equipment and link it to a line with controls that have been obsolete for years, with hardly any wire numbers left and electrical blueprints that don’t match the setup because all of that information was in the head of the engineering old-timer who retired.”

Eby recalls one metalformer that upgraded a few presses while adding feed lines. The old presses employed relatively ancient eddy-current drives that lacked documentation, and personnel were not well-versed in servicing them. By replacing these units with new AC drives, the old, undocumented relay logics and wiring were eliminated, allowing for better feed-line and press operation, and improved serviceability.

As for integration itself, Eby recommends going over quotes with a fine-toothed comb to assess integration responsibility.

“We sometimes find that sales of presses, feeds or transfers do not include full integration of the new equipment into the existing line,” he says. “Metalformers may or may not have the staff on hand for proper integration and documentation, so in an effort to get the line running, integration is performed hurriedly without proper planning and documentation. Do the homework beforehand, which can save headaches later when maintenance, repairs or upgrades are necessary.” MF

See also: Toledo Integrated Systems

Technologies: Pressroom Automation