Page 32 - MetalForming June 2019

P. 32

FABRICATION

Robotic Welding Workcell

Sets New Pace at Freedman Seating

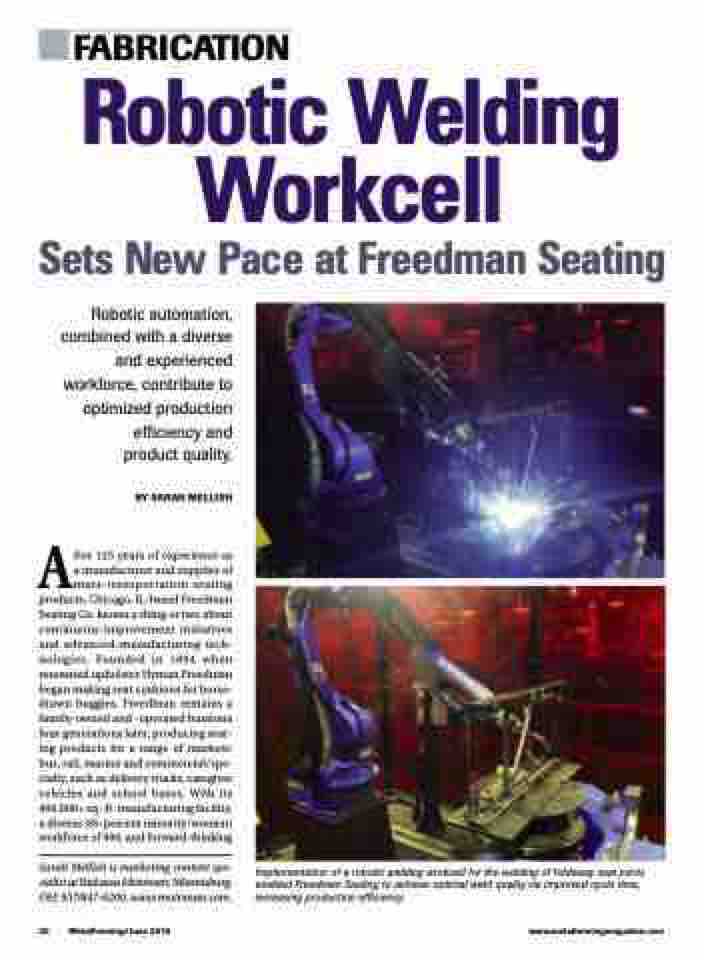

Robotic automation, combined with a diverse and experienced workforce, contribute to optimized production efficiency and product quality.

BY SARAH MELLISH

After 125 years of experience as a manufacturer and supplier of mass-transportation seating products, Chicago, IL-based Freedman Seating Co. knows a thing or two about continuous-improvement initiatives and advanced-manufacturing tech- nologies. Founded in 1894 when renowned upholster Hyman Freedman began making seat cushions for horse- drawn buggies, Freedman remains a family-owned and -operated business four generations later, producing seat- ing products for a range of markets: bus, rail, marine and commercial/spe- cialty, such as delivery trucks, caregiver vehicles and school buses. With its 400,000+ sq.-ft. manufacturing facility, a diverse (85-percent minority/women) workforce of 900, and forward-thinking

Sarah Mellish is marketing content spe- cialist at Yaskawa Motoman, Miamisburg, OH; 937/847-6200, www.motoman.com.

Implementation of a robotic welding workcell for the welding of foldaway seat joints enabled Freedman Seating to achieve optimal weld quality via improved cycle time, increasing production efficiency.

30 MetalForming/June 2019

www.metalformingmagazine.com