Page 24 - MetalForming December 2017

P. 24

Material Traceability, Inventory Tracking

...are among the benefits this manufacturer of pre-engineered steel buildings realizes from its implementation of new ERP software. Software modules manage coil processing, shop-floor routing, work-order management and other functions.

BY BRAD F. KUVIN, PUBLISHER/EDITORIAL DIRECTOR

An ERP system equipped to track sheetmetal coils throughout a product’s lifecycle “relieves you of the time-consuming paperchase...It prints coil tags upon receipt and allows you to reprint them at any time...and incorporates document imaging to store documents within the system and to attach them to each coil, so you can digitally look up Mill Test Reports and other impor- tant information instantaneously.”

So notes an online blog post from ERP-software provider Abis, describing eight ways in which metals-related businesses can leverage ERP software to improve their inventory-tracking capa- bilities. Case in point: CO Building Systems Inc., Ephraim, UT, a

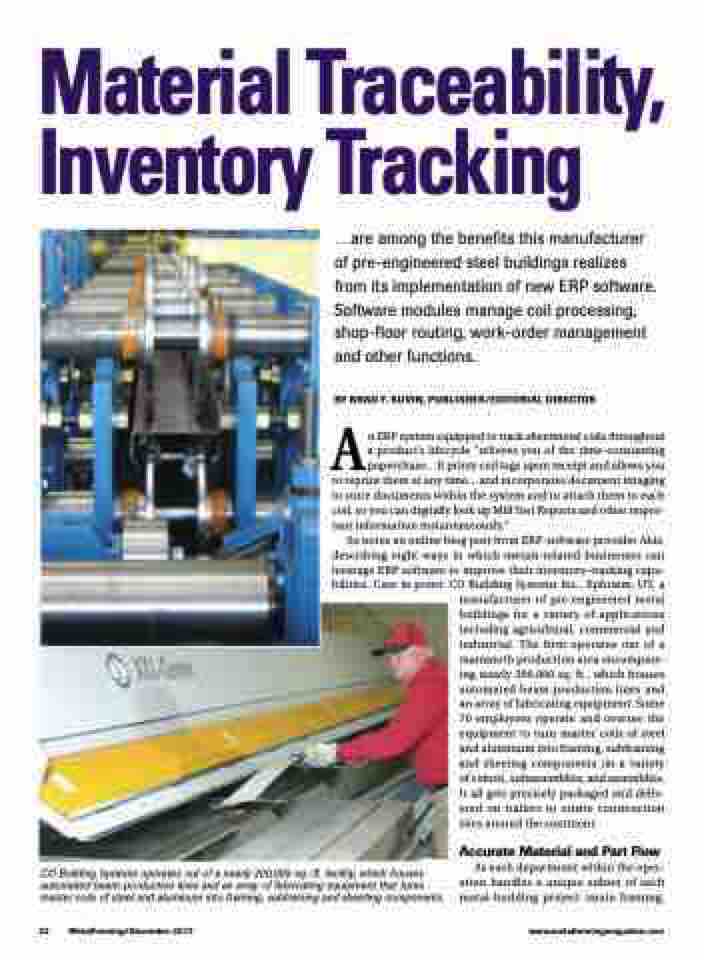

CO Building Systems operates out of a nearly 200,000-sq.-ft. facility, which houses automated beam-production lines and an array of fabricating equipment that turns master coils of steel and aluminum into framing, subframing and sheeting components.

manufacturer of pre-engineered metal buildings for a variety of applications including agricultural, commercial and industrial. The firm operates out of a mammoth production area encompass- ing nearly 200,000 sq. ft., which houses automated beam-production lines and an array of fabricating equipment. Some 70 employees operate and oversee the equipment to turn master coils of steel and aluminum into framing, subframing and sheeting components (in a variety of colors), subassemblies, and assemblies. It all gets precisely packaged and deliv- ered on trailers to onsite construction sites around the continent.

Accurate Material and Part Flow

As each department within the oper- ation handles a unique subset of each metal-building project (main framing,

22 MetalForming/December 2017

www.metalformingmagazine.com